Cemented carbide is a remarkable material widely used in various industrial applications due to its exceptional properties. This composite material, primarily composed of tungsten carbide (WC) particles bonded with a metallic binder, typically cobalt or nickel, offers a unique combination of hardness, wear resistance, and toughness. In this article, we will explore the unique properties of cemented carbide, its applications, and why it is a preferred choice in many industries.

What is Cemented Carbide?

Cemented carbide is a powder metallurgy product created by sintering a mixture of hard carbide particles and a ductile metal binder. The process involves:

- Powder Preparation: Tungsten carbide and cobalt or nickel powders are mixed in specific ratios.

- Compaction: The powder mixture is compacted into the desired shape using high pressure.

- Sintering: The compacted shape is heated in a controlled atmosphere to bond the particles together, resulting in a dense and hard material.

Unique Properties of Cemented Carbide

- High Hardness and Wear Resistance

- Cemented carbide exhibits exceptional hardness, typically ranging from 86 to 93 HRA (equivalent to 69 to 81 HRC). This hardness allows it to maintain its cutting edge even when machining hard materials.

- It can withstand wear and tear, making it ideal for tools and components that experience high friction and abrasion.

- Red Hardness

- Unlike many materials that lose hardness at elevated temperatures, cemented carbide retains its hardness even at temperatures up to 900-1000°C. This property, known as red hardness, is crucial for applications involving high-speed machining.

- High Compressive Strength

- Cemented carbide has a compressive strength of up to 6000 MPa, making it highly resistant to deformation under load. This property is essential for tools and parts subjected to heavy forces.

- Good Corrosion and Oxidation Resistance

- The material exhibits excellent resistance to corrosion and oxidation, allowing it to perform well in harsh environments. This makes cemented carbide suitable for applications in chemical processing and other corrosive settings.

- Low Coefficient of Linear Expansion

- Cemented carbide has a low coefficient of linear expansion, which means it maintains its shape and dimensions under varying temperatures. This stability is critical for precision machining applications.

- Versatile Machinability

- Although cemented carbide is extremely hard, it can be machined using specialized techniques such as electrical discharge machining (EDM) or grinding with diamond tools. This versatility allows for the production of complex shapes and components.

Applications of Cemented Carbide

Cemented carbide is used in a wide range of applications across various industries, including:

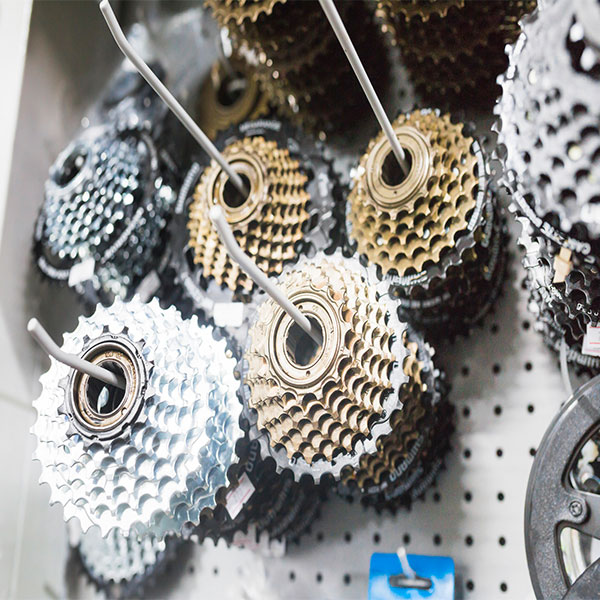

- Cutting Tools: Cemented carbide is the material of choice for manufacturing high-speed cutting tools, such as drills, end mills, and inserts. Its hardness and wear resistance enable efficient machining of hard materials, including steel and cast iron.

- Molds and Dies: Used in the production of cold work molds, cemented carbide is ideal for applications requiring high wear resistance and toughness, such as stamping, forging, and extrusion dies.

- Mining and Drilling: Cemented carbide is extensively used in mining tools, such as drill bits and rock drills, due to its ability to withstand the harsh conditions encountered in drilling operations.

- Wear-Resistant Parts: Components subjected to severe wear, such as valve seats, nozzles, and bearings, benefit from the durability of cemented carbide, extending their service life and reducing maintenance costs.

Why Choose Cemented Carbide?

Cemented carbide stands out due to its unique combination of properties that make it suitable for demanding applications. Its ability to maintain performance under extreme conditions, coupled with its versatility in machining, makes it a preferred material in industries ranging from manufacturing to mining.

Cemented carbide is a remarkable material that offers exceptional hardness, wear resistance, and durability. Its unique properties make it an essential choice for various applications, including cutting tools, molds, and wear-resistant parts. For high-quality cemented carbide products, Nanjing Xing Yi Chen is a trusted supplier, providing solutions tailored to meet the specific needs of different industries. By choosing cemented carbide, businesses can enhance their productivity and ensure the longevity of their tools and components.