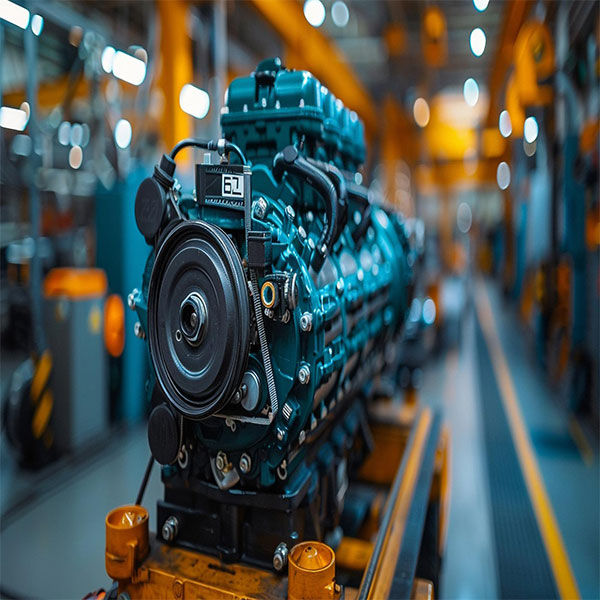

As industries worldwide strive for greater energy efficiency and sustainability, high-efficiency electric motors are emerging as a key component in driving this transformation. With the global stock of electric motors expected to double between 2018 and 2040, the future of high-efficiency motors in manufacturing looks promising. This article explores the trends, benefits, and innovations that are shaping the future of high-efficiency electric motors, highlighting their pivotal role in various sectors.

The Growing Demand for High-Efficiency Motors

The demand for high-efficiency electric motors is being fueled by several factors:

- Rising Energy Costs: Industrial electricity prices have surged by 18% over the past four years, prompting manufacturers to seek ways to reduce energy consumption and operational costs. High-efficiency motors can significantly lower energy bills, making them an attractive investment.

- Sustainability Goals: As companies set ambitious carbon reduction targets, the need for energy-efficient technologies becomes increasingly urgent. High-efficiency motors help reduce CO2 emissions, aligning with global sustainability initiatives.

- Increased Electrification: The global trend toward electrification means that industries are increasingly relying on electric motors for various applications. According to the International Energy Agency, electric motors account for approximately 70% of electricity consumed by industry, making them a critical focus for energy efficiency improvements.

Key Benefits of High-Efficiency Electric Motors

Energy Savings

-

- High-efficiency motors, such as those meeting the NEMA Premium Efficiency (IE3) and Super Premium Efficiency (IE4) standards, can achieve efficiency ratings of up to 96% or higher. This translates to significant energy savings for manufacturers.

- For example, switching to NEMA Super Premium Efficient motors could save U.S. industry approximately $1.68 billion annually.

Reduced Operating Costs

-

- By lowering energy consumption, high-efficiency motors help reduce overall operating costs. This is particularly beneficial for energy-intensive industries like manufacturing, mining, and water treatment.

Enhanced Performance

-

- High-efficiency motors often feature advanced designs and materials that improve performance and reliability. Innovations such as variable speed drives (VSDs) further enhance efficiency by allowing motors to operate at optimal speeds based on demand.

Longer Lifespan

-

- The robust construction of high-efficiency motors often leads to a longer operational lifespan, reducing the frequency of replacements and maintenance costs.

Innovations Shaping the Future

The future of high-efficiency electric motors is being driven by several key innovations:

- New Materials and Designs: Researchers are exploring lightweight, high-strength materials, such as carbon fiber composites, to enhance motor efficiency. Novel designs aim to minimize energy losses due to heat and friction.

- Integration with Smart Technologies: The integration of artificial intelligence (AI) and the Internet of Things (IoT) is allowing for smarter motor systems that can optimize performance and predict maintenance needs. These technologies enable manufacturers to monitor motor performance in real-time, leading to proactive maintenance and reduced downtime.

- Regulatory Changes: Stricter energy efficiency regulations are pushing manufacturers to upgrade to high-efficiency motors. For instance, the European Union has set IE4 as the minimum standard for certain motor types, encouraging the adoption of more efficient technologies.

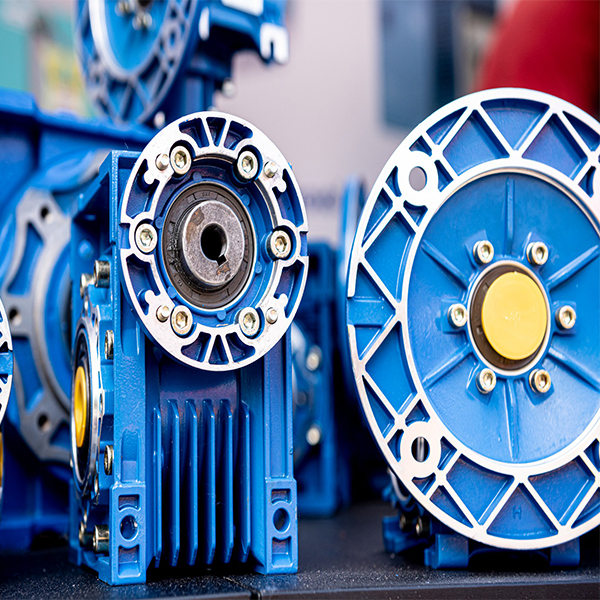

The Role of Nanjing Xing Yi Chen

As industries look to transition to high-efficiency electric motors, Nanjing Xing Yi Chen stands out as an important supplier of these advanced technologies. With a commitment to quality and innovation, Nanjing Xing Yi Chen provides high-efficiency electric motors tailored to meet the diverse needs of various industries. Their comprehensive technical support and after-sales services ensure that customers can optimize their production processes, improve efficiency, and reduce operating costs.

The future of high-efficiency electric motors in global manufacturing is bright, with increasing demand driven by the need for energy savings, sustainability, and improved performance. As innovations continue to shape the industry, high-efficiency motors will play a critical role in helping manufacturers meet their operational goals while reducing their environmental impact. Partnering with suppliers like Nanjing Xing Yi Chen can provide businesses with the cutting-edge technologies and support needed to thrive in this evolving landscape.