In today’s competitive industrial landscape, optimizing production processes is essential for enhancing efficiency, reducing costs, and achieving sustainability goals. High-efficiency electric motors play a pivotal role in this optimization, offering significant advantages over traditional motors. This article explores how these advanced motors contribute to improved production processes across various industries, highlighting their benefits, applications, and the role of Nanjing Xing Yi Chen as a key supplier.

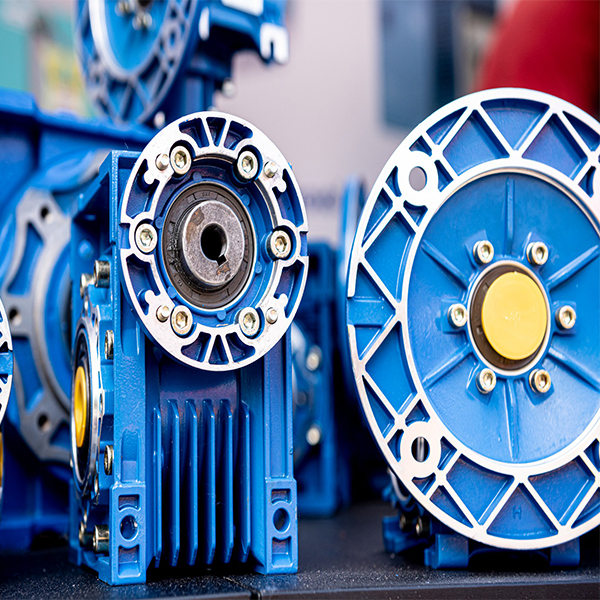

Understanding High-Efficiency Electric Motors

High-efficiency electric motors are designed to convert electrical energy into mechanical energy with minimal losses. They typically meet or exceed standards set by organizations such as the National Electrical Manufacturers Association (NEMA) and the International Electrotechnical Commission (IEC). For instance:

- NEMA Premium Efficiency (IE3) motors achieve efficiencies of approximately 96%.

- NEMA Super Premium (IE4) motors can reduce energy losses by about 15% compared to IE3 motors.

Benefits of High-Efficiency Electric Motors

- Energy Savings

- High-efficiency motors consume less energy, leading to substantial cost savings. In the U.S. alone, switching to NEMA Super Premium Efficient motors could save approximately $billion annually in energy costs.

- These motors are particularly beneficial in applications that run continuously, as the energy savings can be significant over time.

- Reduced Operating Costs

- Lower energy consumption directly translates to reduced operational costs. High-efficiency motors also require less maintenance, further decreasing overall expenses.

- For example, facilities that implement high-efficiency motors can see a reduction in maintenance costs due to fewer breakdowns and longer operational lifespans.

- Improved Performance

- High-efficiency motors are designed with advanced materials and technologies that enhance their performance. This includes better thermal management, which prevents overheating and extends the life of the motor.

- Their ability to maintain high efficiency under varying load conditions ensures consistent performance across different applications.

- Environmental Impact

- By reducing energy consumption and greenhouse gas emissions, high-efficiency motors contribute to sustainability goals. Industries can significantly lower their carbon footprint by transitioning to these advanced motors.

Applications in Various Industries

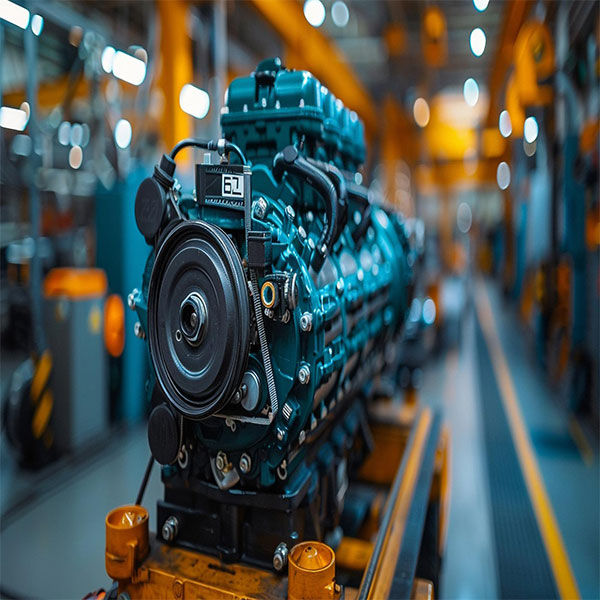

High-efficiency electric motors find applications across a wide range of industries, each benefiting from their unique advantages:

- Manufacturing: In manufacturing facilities, high-efficiency motors power machinery such as conveyors, pumps, and compressors. Their energy savings and reliability enhance overall production efficiency.

- Water Treatment: High-efficiency motors are used in water treatment plants to drive pumps and filtration systems. Their efficiency contributes to effective water management and reduced operational costs.

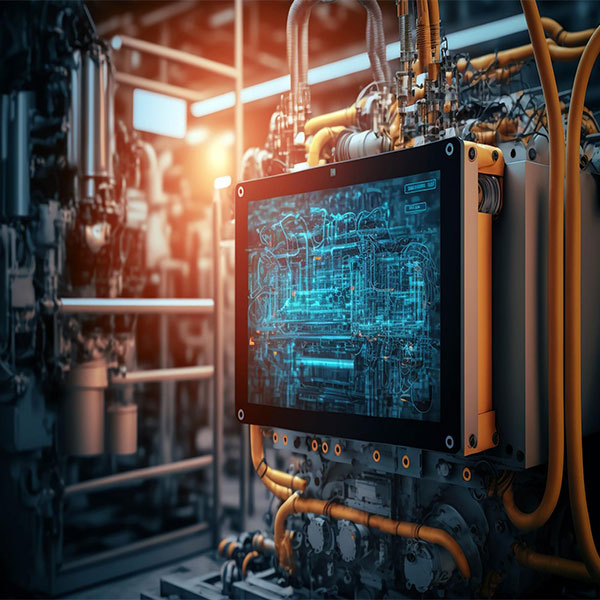

- Oil and Gas: In the oil and gas industry, high-efficiency motors power drilling rigs, compressors, and pumping systems. Their durability and energy efficiency are crucial for continuous operations in harsh environments.

- HVAC Systems: High-efficiency motors are essential in heating, ventilation, and air conditioning (HVAC) systems, where they help maintain optimal climate control while minimizing energy use.

Optimizing Motor Performance

To maximize the benefits of high-efficiency electric motors, organizations should consider the following strategies:

- Proper Sizing: Ensure that motors are appropriately sized for their applications. Oversized motors can lead to inefficiencies, particularly at partial loads.

- Advanced Controls: Pair high-efficiency motors with variable frequency drives (VFDs) to optimize speed and torque based on demand. This combination enhances energy savings and improves overall system performance.

- Regular Maintenance: Implement a proactive maintenance program to monitor motor performance and address potential issues before they escalate. This approach helps maintain efficiency and prolongs motor life.

- Continuous Improvement: Regularly assess motor performance and energy consumption to identify areas for improvement. Gathering feedback from operators can lead to further enhancements in efficiency.

The Role of Nanjing Xing Yi Chen

Nanjing Xing Yi Chen is an important supplier of high-efficiency electric motors, offering innovative solutions tailored to meet the diverse needs of various industries. With a commitment to quality and reliability, Nanjing Xing Yi Chen ensures that its motors help customers optimize their production processes, improve efficiency, and reduce operating costs. Their comprehensive technical support and after-sales services further enhance the value of their products.

High-efficiency electric motors are essential for optimizing production processes in today’s industrial environment. Their energy-saving capabilities, reduced operating costs, and improved performance make them a valuable investment for organizations seeking to enhance efficiency and sustainability. By partnering with suppliers like Nanjing Xing Yi Chen, businesses can access the high-quality motors and support needed to thrive in a competitive market.