High-efficiency motors are increasingly recognized for their outstanding performance across a wide range of industrial applications. These advanced motors provide significant advantages over traditional models, particularly in energy savings, operational efficiency, and environmental impact. Below is an overview of how high-efficiency motors excel in different sectors.

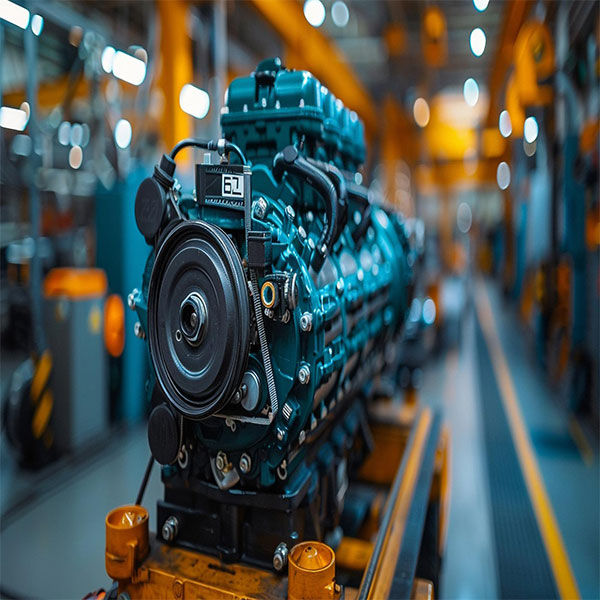

- Oil and Gas Industry

High-efficiency motors are essential in the oil and gas sector, powering critical equipment such as pumps, compressors, and drilling rigs.

- Energy Savings: By utilizing high-efficiency motors, companies can reduce energy consumption by up to 40% compared to traditional motors. This results in substantial cost savings, especially for operations that run continuously.

- Reliability: The robust design of high-efficiency motors ensures reliable performance in harsh environments, contributing to safer and more efficient operations.

- Refinery Applications

In refineries, high-efficiency motors drive essential processes, including distillation, mixing, and pumping.

- Operational Efficiency: These motors can achieve efficiencies of up to 96%, significantly reducing energy losses. For example, a 200 kW AC induction motor that meets NEMA Premium Efficiency standards operates at approximately 96% efficiency, leading to lower operational costs.

- Reduced Maintenance: High-efficiency motors typically have longer lifespans and require less frequent maintenance, minimizing downtime and enhancing production continuity.

- Power Generation

High-efficiency motors play a vital role in power generation facilities by driving generators and auxiliary systems.

- Performance Improvement: By enhancing energy conversion rates, high-efficiency motors contribute to the overall efficiency of power plants. Motors that meet IE4 and IE5 standards can provide up to 15% less energy loss compared to traditional motors.

- Sustainability Alignment: The use of high-efficiency motors in power generation supports sustainability goals by helping to reduce greenhouse gas emissions.

- Water Treatment Facilities

In water treatment facilities, high-efficiency motors are essential for powering pumps and filtration systems.

- Energy Efficiency: Upgrading to IE5 motors can lead to a 27% reduction in overall energy costs in large facilities.

- Enhanced Reliability: These motors are designed to operate efficiently under varying load conditions, ensuring consistent performance in critical water management applications.

- Mining Operations

High-efficiency motors are increasingly used in mining operations to power conveyor systems, crushers, and ventilation systems.

- Durability: The rugged construction of high-efficiency motors allows them to withstand the demanding conditions found in mining environments, enhancing reliability and reducing the likelihood of failure.

- Cost Savings: Transitioning to high-efficiency motors enables mining companies to achieve substantial energy savings—critical in an industry where energy costs represent a significant portion of operational expenses.

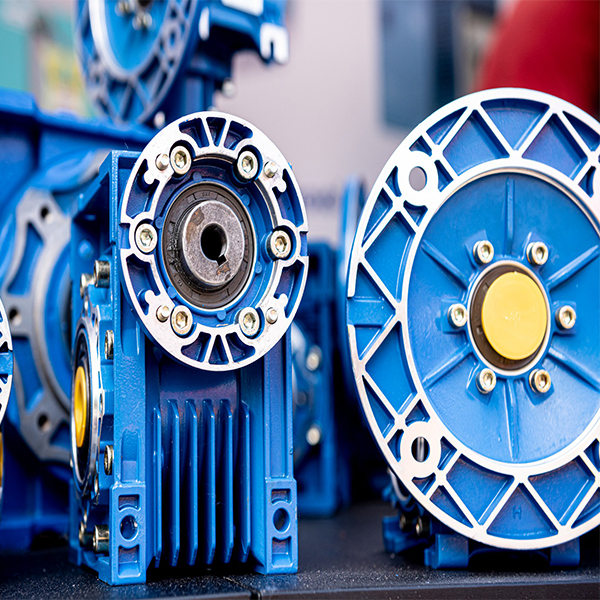

- Manufacturing and Industrial Automation

High-efficiency motors are widely employed in manufacturing processes, powering machinery such as conveyors, fans, and compressors.

- Versatility: These motors can be integrated with variable speed drives (VSDs) to optimize performance based on demand, leading to further energy savings.

- Improved Power Factor: High-efficiency motors typically have a power factor close to 1, which enhances the overall quality of the power grid and reduces energy losses.

High-efficiency motors are revolutionizing industrial applications by delivering significant energy savings, improved operational efficiency, and enhanced reliability. Their performance across sectors such as oil and gas, refining, power generation, water treatment, mining, and manufacturing highlights their critical role in modern industry. As companies increasingly focus on sustainability and cost reduction, the adoption of high-efficiency motors will continue to rise.

For those seeking high-quality high-efficiency motors tailored to their specific needs, Nanjing Xing Yi Chen is an important supplier offering a comprehensive range of solutions designed for various industrial applications. By investing in high-efficiency motors, businesses can not only lower their operational costs but also contribute to a more sustainable future.