In today’s fast-paced industrial environments, air compressors are essential for powering various tools and machinery, making production processes more efficient and reliable. But how exactly do industrial air compressors work, and why are they so crucial across different industries? In this complete guide, we’ll break down the basic principles of industrial air compressors, explore their core features, and discuss their applications in manufacturing, energy, and beyond.

Introduction: The Importance of Industrial Air Compressors

At their core, industrial air compressors convert power (typically from an electric motor or diesel engine) into potential energy stored in pressurized air. This pressurized air can then be released in a controlled manner to power a wide range of machinery and tools, from pneumatic drills to automated production equipment.

Industrial air compressors are widely used across industries because they provide a reliable and efficient energy source. Whether you’re in manufacturing, construction, or energy production, air compressors offer the versatility needed to keep your operations running smoothly and efficiently.

How Do Industrial Air Compressors Work?

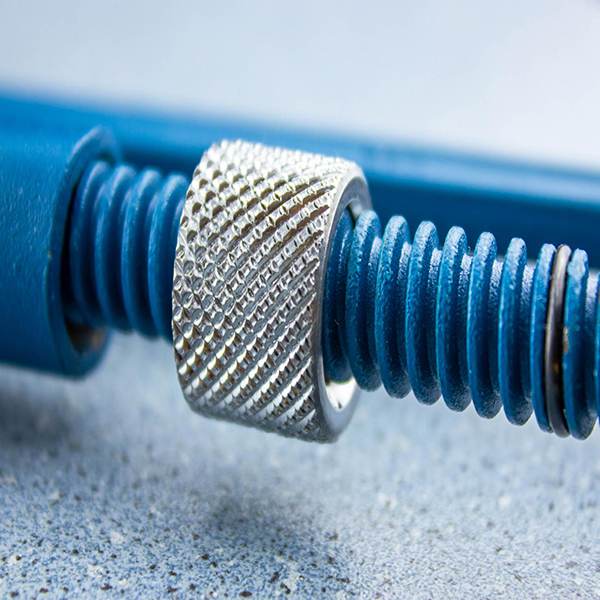

The basic working principle of an air compressor involves taking in ambient air, compressing it to a higher pressure, and storing it in a tank or directly releasing it for use in powering machinery. The key components of an air compressor include:

- Intake Valve: Draws in air from the surrounding environment.

- Compressor Pump: Compresses the air, reducing its volume and increasing its pressure.

- Storage Tank: Holds the pressurized air until it’s needed.

- Control System: Regulates the pressure and releases the air in a controlled flow.

Industrial air compressors come in various types, each serving different needs:

- Reciprocating Compressors: These compressors use a piston-driven mechanism to compress air. They are commonly used in smaller-scale industries or workshops for intermittent use.

- Rotary Screw Compressors: Featuring rotating screws to compress air, these compressors are ideal for large-scale industrial applications where continuous, high-volume air is required.

- Centrifugal Compressors: Designed for large industrial plants, centrifugal compressors use a high-speed rotating impeller to generate pressurized air efficiently.

Industrial Applications of Air Compressors

Air compressors play a vital role in industries like manufacturing, construction, and energy. Here are a few key applications:

- Manufacturing: In factories, air compressors power tools, automate production lines, and manage pneumatic controls for precision manufacturing.

- Construction: Air compressors are used to power heavy-duty tools such as pneumatic drills, hammers, and jackhammers, making them indispensable on construction sites.

- Energy and Oil & Gas: In energy production, air compressors are used in systems for power generation, oil extraction, and natural gas transport.

These industries rely on air compressors not only for their versatility but also for their ability to enhance productivity and minimize downtime.

Key Features of Industrial Air Compressors

When choosing an air compressor for industrial use, it’s crucial to consider the following key features:

- Energy Efficiency: Modern air compressors, like Atlas Copco’s advanced models, are designed to use energy efficiently, helping companies reduce their operational costs and environmental footprint.

- Durability: Industrial air compressors are built to withstand harsh working environments and operate reliably over long periods with minimal maintenance.

- Capacity & Pressure: Depending on the application, the capacity (measured in cubic feet per minute – CFM) and pressure (measured in pounds per square inch – PSI) of the compressor must meet the specific requirements of the machinery or tools in use.

Why Choose Atlas Copco Air Compression Solutions?

When it comes to industrial air compression solutions, Atlas Copco stands out as a leader in delivering reliable and energy-efficient compressors. Their rotary screw compressors are renowned for offering continuous air supply, minimal maintenance needs, and high durability—making them ideal for heavy-duty industrial applications.

Compared to other brands, Atlas Copco compressors provide superior performance, helping businesses optimize their energy consumption and reduce long-term costs. By investing in an Atlas Copco air compressor, you ensure that your operations run smoothly, efficiently, and with minimal downtime.

Ensuring Efficient Operations with the Right Air Compressor

Understanding how industrial air compressors work and selecting the right type for your specific application is crucial for maintaining productivity in an industrial environment. Whether you’re running a manufacturing plant, construction site, or energy production facility, investing in the right air compression solution can make all the difference.

To learn more about how Nanjing XYC can help you find the perfect air compressor for your business, explore our range of Atlas Copco industrial air compression solutions, or contact us for a consultation and quote today!