In today’s competitive industrial landscape, efficiency and reliability are paramount. Atlas Copco air compressors have become a vital component in various sectors, providing the compressed air needed to power machinery and optimize processes. This article explores the top applications of Atlas Copco air compressors in different industries, highlighting their versatility, performance, and essential role in modern operations.

- Manufacturing: Powering Production Lines

In manufacturing environments, the need for consistent and reliable compressed air is crucial. Atlas Copco air compressors are commonly used to power pneumatic tools, automate production processes, and control machinery. Whether in automotive assembly, electronics manufacturing, or food processing, these compressors ensure that production lines operate smoothly and efficiently.

The use of Atlas Copco compressors in manufacturing enhances productivity by providing a continuous air supply, which is vital for tasks like:

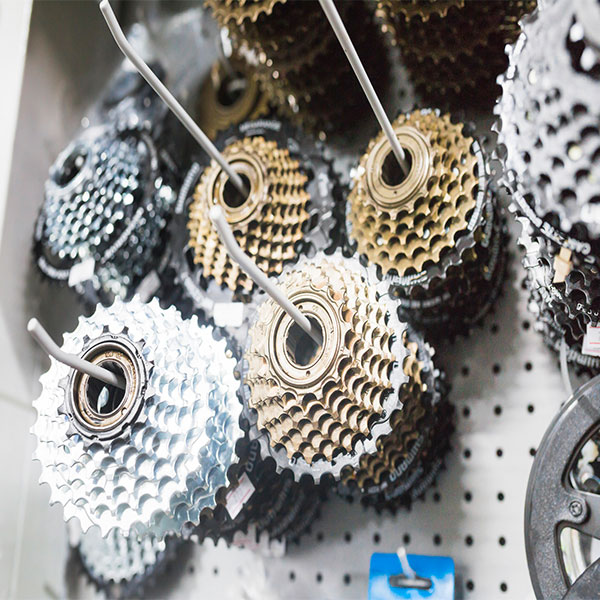

- Pneumatic Tool Operation: Drills, wrenches, and grinders rely on compressed air for efficient operation.

- Automation Systems: Compressed air is essential for actuators and control systems, ensuring precise and responsive machinery.

- Packaging Processes: In industries like food and beverage, air compressors are used for packaging and sealing processes that require sterile environments.

- Construction: Enhancing Site Productivity

In the construction industry, Atlas Copco air compressors are indispensable for powering heavy-duty equipment and tools. Their ability to deliver high volumes of compressed air makes them ideal for various applications, including:

- Pneumatic Tools: Compressors provide the air needed for tools like jackhammers, nail guns, and concrete vibrators, improving efficiency and reducing labor costs.

- Dust Suppression: In construction sites, air compressors can be used to power dust control systems, ensuring a safer working environment.

- Hydraulic Systems: Many construction equipment relies on compressed air to operate hydraulic systems, enabling smooth operation and lifting capabilities.

Atlas Copco’s portable air compressors are particularly popular in construction due to their robustness and ease of transport, making them ideal for job sites.

- Energy Sector: Supporting Operations

The energy sector, including oil, gas, and renewable energy, relies heavily on Atlas Copco air compressors for various operations. Their applications include:

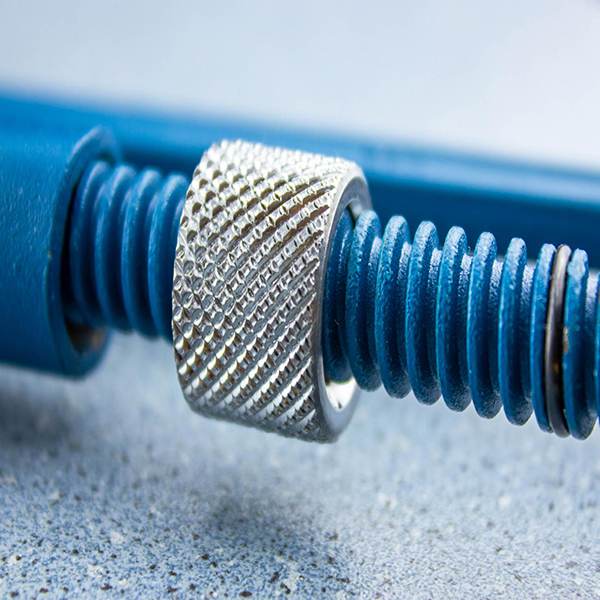

- Drilling Operations: Air compressors power drilling rigs, ensuring consistent pressure for drilling operations in oil and gas extraction.

- Pipeline Maintenance: Compressed air is used for cleaning and maintaining pipelines, helping to prevent blockages and ensure efficient flow.

- Renewable Energy Solutions: In wind and solar energy installations, air compressors are utilized for maintenance and operational tasks, ensuring optimal performance.

With the energy sector facing increasing demands for efficiency and sustainability, Atlas Copco compressors provide the reliability needed to meet these challenges.

- Automotive: Precision and Efficiency

In the automotive industry, precision and quality are non-negotiable. Atlas Copco air compressors are used in various applications, including:

- Paint Shop Operations: Compressed air is vital for spray painting and finishing processes, ensuring a smooth and even application.

- Assembly Lines: Air compressors power tools used in assembling vehicles, contributing to faster and more efficient production cycles.

- Testing and Quality Control: Compressed air is used in various testing equipment to simulate operating conditions, ensuring product reliability and safety.

By using Atlas Copco compressors, automotive manufacturers can enhance their production quality while reducing operational costs.

- Food and Beverage: Ensuring Safety and Hygiene

In the food and beverage industry, the use of compressed air must adhere to strict hygiene standards. Atlas Copco provides food-grade air compressors that meet regulatory requirements and ensure safety in processing and packaging. Key applications include:

- Food Packaging: Compressed air is used for sealing packages, ensuring freshness and preventing contamination.

- Bottling Processes: Air compressors power machinery that cleans, fills, and caps bottles, ensuring high-speed and efficient operations.

- Process Automation: Compressed air operates valves, actuators, and other equipment in food processing, enhancing efficiency and maintaining safety standards.

Atlas Copco’s commitment to providing clean, reliable compressed air solutions makes them a trusted partner in the food and beverage industry.

The Versatility of Atlas Copco Air Compressors

Atlas Copco air compressors play a crucial role in various industries, offering reliable, efficient, and versatile solutions tailored to meet specific operational needs. Whether in manufacturing, construction, energy, automotive, or food processing, these compressors enhance productivity, reduce costs, and improve overall operational efficiency.

For businesses looking to optimize their processes with the best air compression solutions, Atlas Copco offers a range of products designed to meet the highest standards. Explore our selection at Nanjing XYC and discover how Atlas Copco air compressors can elevate your industrial operations today!