In today’s industrial landscape, energy efficiency is more than just a goal; it’s a necessity. With rising energy costs and increasing pressure to reduce carbon footprints, optimizing energy usage in industrial processes is critical. Atlas Copco air compressors are at the forefront of this initiative, offering innovative solutions that not only enhance operational efficiency but also contribute to significant energy savings. This article explores practical strategies to optimize energy efficiency with Atlas Copco air compressors, ensuring that your operations are both sustainable and cost-effective.

Choose the Right Compressor for Your Needs

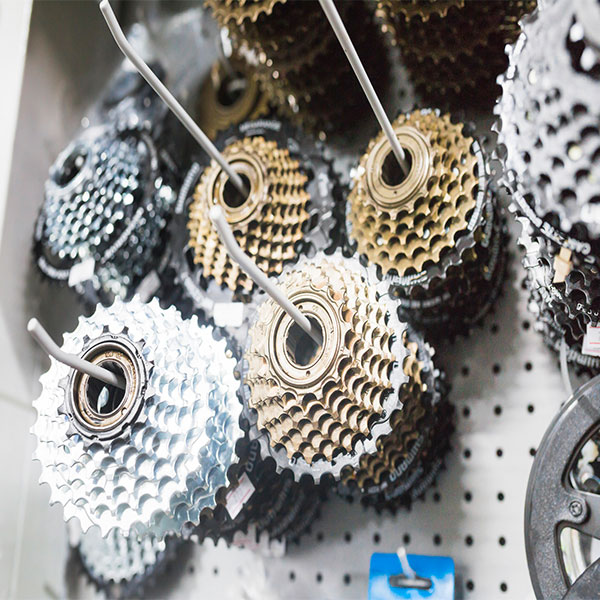

Selecting the appropriate compressor type and model is the first step toward maximizing energy efficiency. Atlas Copco offers a diverse range of air compressors designed for various applications. Consider the following:

- Assess Your Air Demand: Evaluate your specific air requirements, including pressure and flow rate. Atlas Copco provides tools and guidance to help determine the best fit for your application.

- Consider Variable Speed Drive (VSD) Models: Opting for compressors with VSD technology allows for automatic adjustment of motor speed based on air demand, significantly reducing energy consumption during low-demand periods.

Regular Maintenance is Key

Keeping your Atlas Copco air compressor in optimal working condition is vital for energy efficiency. Implement a proactive maintenance schedule that includes:

- Routine Inspections: Regularly check for leaks, which can lead to energy waste. Even small leaks can significantly impact efficiency.

- Air Filter Replacement: Clogged filters restrict airflow, forcing the compressor to work harder and consume more energy. Replace filters according to the manufacturer’s recommendations.

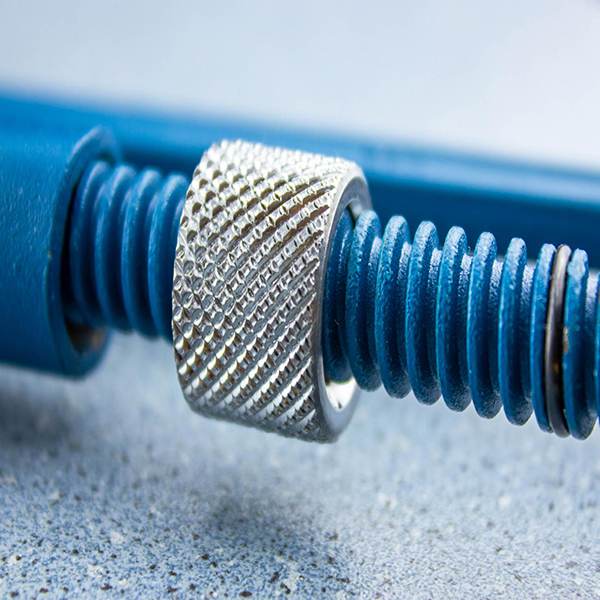

Optimize Air Piping Systems

The layout and condition of your air piping system play a crucial role in energy efficiency. Follow these best practices:

- Minimize Pressure Drops: Ensure that your piping system is designed to minimize pressure losses. Use the correct pipe diameter and minimize bends and turns in the piping.

- Isolate Zones of Use: Consider using zone control to direct compressed air only where it is needed, preventing unnecessary energy use in areas not requiring compressed air.

Utilize Air Dryers and Filters

Maintaining the quality of your compressed air is essential for efficiency. Atlas Copco offers advanced air treatment solutions, including:

- Refrigerated and Desiccant Air Dryers: These units remove moisture from compressed air, preventing corrosion and improving system performance.

- High-Quality Filters: Installing high-efficiency filters will help remove contaminants, ensuring that the compressed air is clean and reducing wear on downstream equipment.

Implement Smart Controls and Monitoring

Atlas Copco compressors come equipped with advanced control systems that facilitate energy optimization:

- Smart Control Systems: Utilize built-in smart controls to manage air supply dynamically, adjusting output based on real-time demand.

- Remote Monitoring: Invest in remote monitoring tools that allow you to track compressor performance and energy usage, enabling data-driven decisions for energy optimization.

Train Your Staff

Ensure that your team understands how to operate and maintain the compressor system efficiently. Training sessions can cover:

- Energy-Conscious Operations: Educate operators about best practices for using compressors, including avoiding overloading and unnecessary operation.

- Safety Protocols: Emphasizing safety while maintaining efficiency can prevent accidents and ensure a productive work environment.

Consider Upgrading Equipment

If your current air compressor system is outdated, consider upgrading to the latest Atlas Copco models that incorporate cutting-edge energy-saving technologies. Newer compressors are designed with improved energy efficiency and lower operational costs in mind.

Take Action Towards Energy Efficiency

Optimizing energy efficiency with Atlas Copco air compressors not only enhances operational productivity but also contributes to significant cost savings and environmental sustainability. By carefully selecting equipment, maintaining it regularly, optimizing your air system, and utilizing advanced control technologies, you can maximize the efficiency of your compressed air operations.

Explore the extensive range of Atlas Copco air compressors available at Nanjing XYC and take the first step toward a more energy-efficient future for your industrial operations.