Atlas Copco stands as a leading name in air compression technology, providing efficient, sustainable solutions across industries worldwide. Known for their precision engineering and innovation, Atlas Copco air compressors offer unmatched reliability and performance, making them an ideal choice for diverse applications in manufacturing, automotive, energy, and more. In this guide, we’ll explore the innovations that set Atlas Copco compressors apart and why they’re trusted across various sectors for meeting rigorous demands.

Key Innovations in Atlas Copco Air Compressors

1. Energy-Efficient Design

Atlas Copco has pioneered energy-efficient air compression systems, emphasizing designs that minimize energy waste and reduce operating costs. Their compressors include advanced engineering features that deliver optimal performance while conserving resources, ensuring significant cost savings in the long run.

2. Variable Speed Drive (VSD) Technology

Atlas Copco’s Variable Speed Drive (VSD) technology is a standout feature, designed to automatically adjust the compressor’s motor speed based on demand. This smart technology can save up to 50% in energy costs by only producing as much compressed air as needed, avoiding energy loss during low-demand periods. VSD technology also extends the lifespan of the compressor, offering both economic and environmental benefits.

3. Oil-Free Compression

For industries that require contaminant-free air—such as food and beverage, pharmaceuticals, and electronics—Atlas Copco offers an extensive line of oil-free compressors. These systems meet strict international standards for air purity, ensuring that production processes remain clean and safe. Atlas Copco’s oil-free compressors are trusted for applications where air quality is a top priority, providing reliable and safe solutions.

4. Advanced Monitoring and Control Systems

Atlas Copco integrates intelligent monitoring and control systems that allow users to oversee air pressure, energy consumption, and equipment maintenance needs in real time. With features like remote monitoring and analytics, these systems provide valuable insights for operators, allowing them to optimize performance, reduce downtime, and proactively manage maintenance. This level of control is particularly valuable in larger facilities where efficiency and uptime are critical.

5. Compact and Modular Designs

Atlas Copco’s compact and modular designs allow for easy installation and flexibility in facility layouts. This modularity also allows businesses to expand their air compression capacity easily as operational needs grow. These compressors take up less floor space and simplify the setup process, providing versatile solutions for both large industrial plants and smaller workspaces.

Applications Across Diverse Industries

Atlas Copco air compressors are designed to meet the demands of a wide range of industries:

• Manufacturing – Ensuring smooth and efficient production with consistent air pressure.

• Automotive – Delivering precise, clean air for tools and assembly processes.

• Food and Beverage – Providing oil-free, contaminant-free air to uphold stringent safety standards.

• Pharmaceuticals – Supporting clean air environments necessary for sensitive production processes.

• Electronics – Ensuring high-purity air critical for manufacturing sensitive electronic components.

• Energy Sector – Enhancing efficiency in power plants and energy production processes.

Nanjing XYC: Your Partner for Atlas Copco Solutions

As an authorized supplier of Atlas Copco compressors, Nanjing XYC offers a full range of air compression solutions tailored to meet your operational requirements. Our experienced team is here to help you select the best Atlas Copco compressor for your industry needs, optimizing performance and energy efficiency. Contact Nanjing XYC today to learn how Atlas Copco compressors can support and enhance your business.

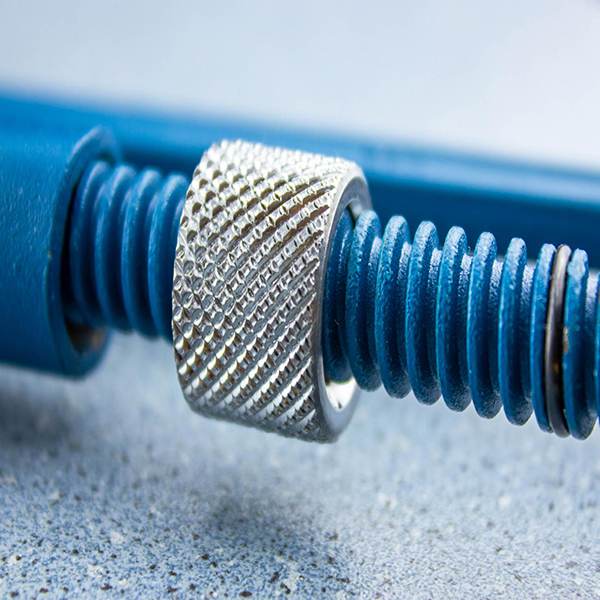

The Role of Air Compressors in Precision Tool Manufacturing

In the competitive world of precision tool manufacturing, efficiency, reliability, and cost savings are critical. Industrial air compressors play a…