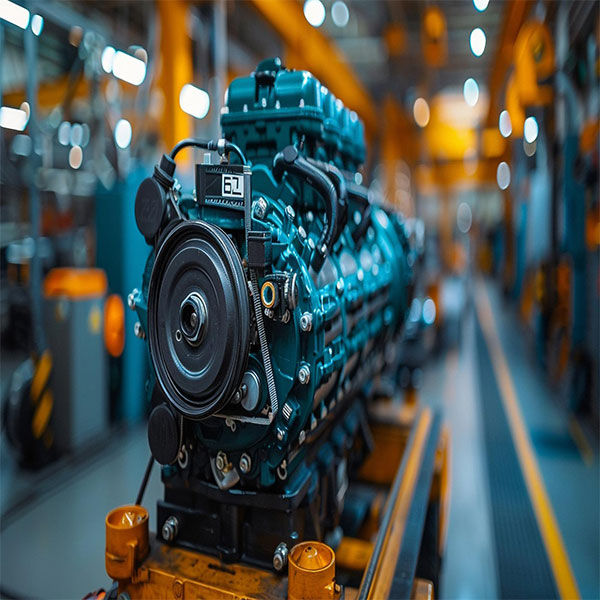

In today’s large-scale manufacturing facilities, the demand for power and efficiency is paramount. Manufacturing plants in sectors such as automotive, steel, chemicals, and paper rely on heavy-duty machinery and continuous operations to meet production targets and quality standards. To ensure smooth and efficient production, manufacturers need robust, high-performance motors that can sustain heavy loads and function reliably under challenging conditions. WEG motors have become a preferred choice for these applications due to their durability, energy efficiency, and the advanced technology that meets the rigorous demands of industrial settings. Below, we’ll explore why WEG motors are essential in large-scale manufacturing plants and how they contribute to optimal productivity.

Exceptional Durability for High-Stress Environments

Manufacturing plants require motors that can withstand intense working conditions, including high temperatures, high moisture, and heavy loads. WEG motors are engineered with materials and design elements that enhance durability, allowing them to operate effectively even in high-stress environments. With reinforced insulation, corrosion-resistant components, and designs optimized for heat dissipation, these motors are built to perform reliably over long periods with minimal downtime. This durability minimizes maintenance requirements and ensures that production lines continue to operate without costly interruptions.

High Energy Efficiency for Cost-Effective Operations

Energy costs in large manufacturing facilities can be substantial, making energy efficiency a top priority for plant operators. WEG motors are designed to maximize energy efficiency, which directly translates into reduced operational costs. Many WEG motor models feature Variable Frequency Drive (VFD) compatibility, which allows the motor’s speed to be adjusted based on demand, reducing unnecessary energy consumption. This feature is particularly beneficial in manufacturing plants, where demand may vary throughout different stages of production. By lowering energy usage, WEG motors help manufacturers reduce costs and meet environmental compliance standards.

Precision and Consistency in Production

One of the critical requirements in large-scale manufacturing is the need for precise and consistent performance. WEG motors are engineered with advanced control technologies, ensuring consistent torque and speed control that meet the precision demands of manufacturing processes. This level of accuracy is essential in sectors such as automotive and electronics manufacturing, where even minor deviations can affect product quality. By delivering consistent power output, WEG motors enable manufacturers to maintain the quality standards their customers expect.

Reduced Downtime with Advanced Reliability Features

In manufacturing plants, downtime can lead to significant losses. WEG motors are designed with reliability features that reduce the risk of unexpected breakdowns. High-quality bearings, specialized insulation systems, and cooling mechanisms ensure that these motors can run continuously with minimal wear and tear. Additionally, WEG motors are equipped with smart monitoring capabilities, allowing operators to track performance, detect issues early, and conduct preventative maintenance. This proactive approach to motor maintenance helps manufacturers minimize unplanned downtime, keeping operations running smoothly.

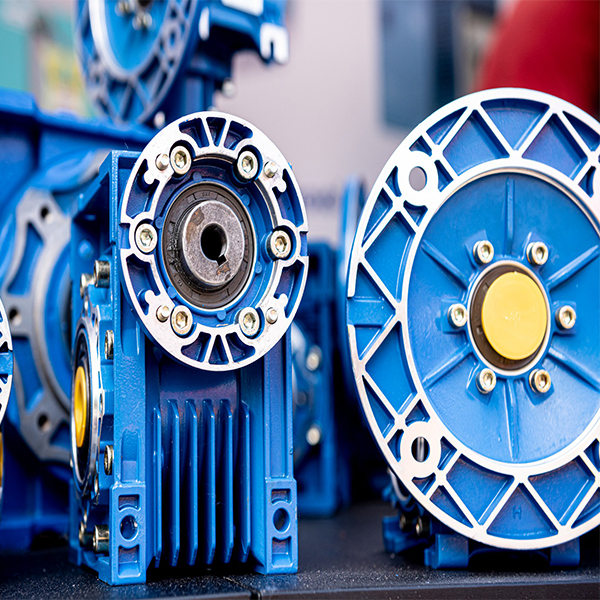

Flexibility Across Diverse Manufacturing Applications

WEG motors come in various configurations and capacities, making them suitable for a wide range of manufacturing applications. Whether a facility requires high-torque motors for heavy-duty applications or precision motors for delicate processes, WEG offers models tailored to each need. For example, in steel manufacturing, where high-power motors are necessary to drive rolling mills and conveyors, WEG provides models that can handle high loads and maintain stable performance. In contrast, for applications like material handling, where precise control is essential, WEG’s versatile motor designs ensure smooth and efficient operation.

Supporting Sustainable Manufacturing Goals

Many large-scale manufacturing plants are aiming to reduce their environmental footprint and meet global sustainability standards. WEG motors support these goals by offering energy-efficient models that reduce greenhouse gas emissions associated with high energy consumption. Additionally, WEG’s commitment to sustainability extends to the manufacturing of the motors themselves, with processes that minimize waste and optimize resource use. For manufacturers, this means that investing in WEG motors aligns with broader sustainability efforts and can help in achieving regulatory compliance in eco-sensitive markets.

Nanjing XYC: Your Source for WEG Motors in Industrial Applications

As a key supplier of WEG motors, Nanjing XYC is committed to providing reliable and efficient motor solutions tailored to the needs of large-scale manufacturing plants. Our experts are available to help you select the right motor model that meets your specific production demands and efficiency goals. Contact Nanjing XYC to learn more about WEG motors and how they can enhance the performance, reliability, and sustainability of your manufacturing operations.

Why WEG Motors Are Critical for Efficient HVAC Systems in Industrial Buildings

Enhancing Industrial Operations with WEG High Voltage Motors In today’s industrial landscape, the need for highly efficient and reliable machinery…