Industrial air compressors are vital components in a wide range of industries, powering tools, machinery, and systems that drive productivity. However, improper use or neglect of safety protocols can lead to accidents, equipment damage, or operational downtime. Understanding and implementing key safety practices is crucial for ensuring the longevity of your air compressors and the well-being of personnel.

1. Perform Regular Maintenance Checks

Routine maintenance is the cornerstone of safe air compressor operation. Scheduled inspections ensure that the equipment operates efficiently and reduces the risk of breakdowns or hazards. Key tasks include:

• Checking and replacing filters regularly to prevent contamination.

• Monitoring oil levels and changing oil as specified in the manufacturer’s guidelines.

• Inspecting hoses and seals for wear and tear to avoid leaks.

2. Ensure Proper Ventilation

Air compressors generate heat during operation, which, if not managed, can lead to overheating or equipment failure. Always install compressors in well-ventilated areas to allow proper heat dissipation and prevent the buildup of dangerous fumes.

3. Train Personnel in Safe Usage

Operators should be adequately trained to handle industrial air compressors. Training should include understanding operational manuals, recognizing warning signs of malfunction, and knowing emergency shut-off procedures.

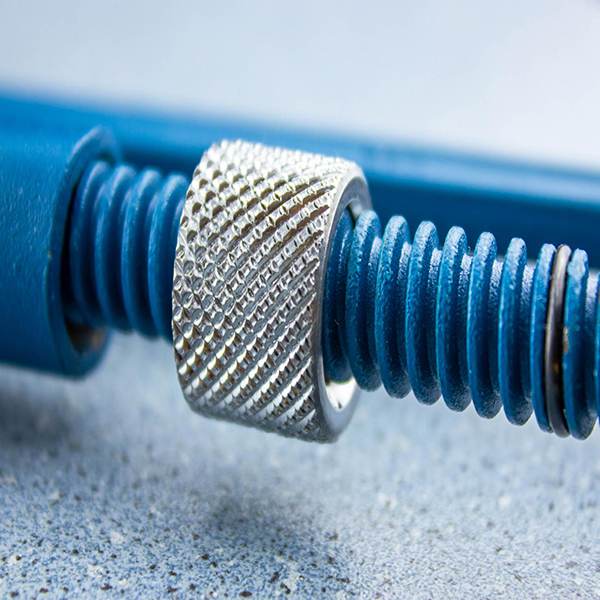

4. Use the Correct Accessories and Components

Using non-compatible or substandard accessories, such as hoses, fittings, or couplers, can lead to performance issues and safety risks. Always use components that match the specifications provided by the compressor manufacturer.

5. Monitor Pressure Levels

Exceeding the recommended pressure level can cause damage to the compressor or connected tools, potentially resulting in accidents. Regularly monitor the pressure gauge and ensure the system’s relief valves are functional to release excess pressure safely.

6. Avoid Overloading the Compressor

Running an air compressor beyond its rated capacity can lead to overheating, reduced efficiency, and premature wear. Match the compressor’s capacity to the demands of your tools and applications to prevent overloading.

7. Implement Lockout/Tagout Procedures

During maintenance or repairs, always follow proper lockout/tagout protocols to ensure the compressor cannot be accidentally activated. This step is critical for protecting technicians and preventing damage to the equipment.

8. Keep the Area Clean and Clear

The surroundings of an air compressor should be free from debris, flammable materials, and other hazards. A clean workspace minimizes the risk of fire and makes it easier to access the compressor for maintenance or emergency shut-offs.

9. Inspect for Air Leaks

Leaking air not only wastes energy but can also indicate a more significant issue within the system. Perform regular leak checks and address any leaks promptly to maintain operational safety and efficiency.

10. Wear Appropriate Personal Protective Equipment (PPE)

Operators should wear appropriate PPE, including safety goggles, ear protection, gloves, and steel-toed boots, to protect against potential hazards such as debris, noise, or accidental falls.

Ensuring Long-Term Safety

By following these safety practices, industries can maximize the reliability and efficiency of their air compressors while minimizing risks to equipment and personnel. Always prioritize adherence to manufacturer guidelines and invest in quality systems that meet the specific needs of your operations.

Nanjing XYC: Your Partner in Reliable Industrial Air Compression Solutions

At Nanjing XYC, we prioritize safety and efficiency in every product we supply. As a trusted provider of high-quality industrial air compressors, we ensure that your operations remain smooth and secure. Contact our experts today for guidance on selecting, maintaining, and operating air compressors tailored to your industry’s needs. Let us help you achieve optimal performance and safety standards.

Energy Efficiency Innovations by Atlas Copco That Save You Money

In today’s highly competitive industrial landscape, operational efficiency and energy savings are key priorities for manufacturers, power plants, and oil…