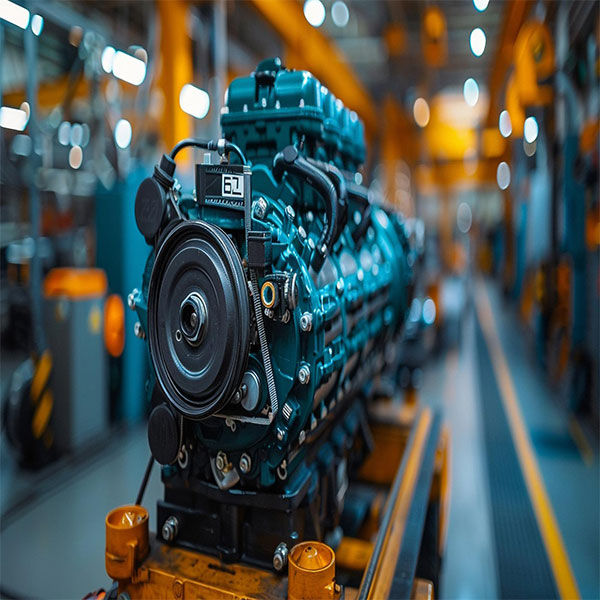

The oil and gas industry is one of the most energy-intensive sectors, requiring robust equipment to handle heavy workloads while ensuring operational efficiency. High voltage motors are at the heart of various applications, including drilling, pumping, and compression. Among these, WEG high voltage motors have emerged as a leader in driving energy savings, enhancing operational performance, and ensuring sustainability in this critical industry.

Optimized Energy Consumption

WEG high voltage motors are engineered with advanced energy-efficient technologies. By employing innovative winding designs and precision manufacturing, these motors minimize energy loss during operation. The result is a significant reduction in power consumption without compromising performance, allowing oil and gas companies to lower operational costs.

High Efficiency Across Applications

Oil and gas processes such as pipeline transport, natural gas compression, and refinery operations demand motors capable of handling diverse and complex tasks. WEG high voltage motors are designed to deliver superior efficiency even under high loads and challenging conditions, ensuring reliable performance with minimal energy waste.

Advanced Variable Speed Drive (VSD) Compatibility

One of the standout features of WEG motors is their compatibility with Variable Speed Drives (VSDs). VSDs enable precise control of motor speed, allowing energy use to be optimized based on real-time demands. This adaptability not only extends motor life but also ensures that energy is not wasted during low-demand periods—a crucial factor in oil and gas operations.

Durability Reduces Resource Consumption

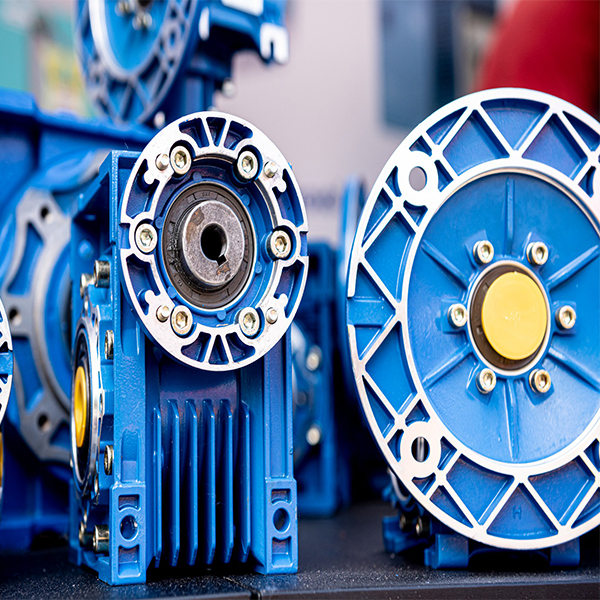

Durability plays a key role in energy savings. WEG motors are built with robust materials and high-grade insulation systems that withstand extreme temperatures, dust, and moisture prevalent in oil and gas environments. The reduced frequency of breakdowns and maintenance translates to less energy used in repairs and replacements, aligning with sustainability goals.

Compliance with Global Efficiency Standards

WEG high voltage motors meet or exceed international efficiency standards such as IE3 and IE4. Compliance with these standards ensures that the motors deliver energy savings while adhering to environmental regulations, making them a preferred choice for oil and gas companies focused on reducing their carbon footprint.

Lower Total Cost of Ownership (TCO)

Beyond energy savings, WEG motors contribute to a lower total cost of ownership. Their energy-efficient operation, combined with minimal downtime and maintenance costs, makes them a long-term investment for oil and gas facilities aiming to achieve operational excellence and cost control.

Partnering for a Sustainable Future

The oil and gas industry is at a turning point where energy efficiency is no longer optional but essential for competitiveness and sustainability. WEG high voltage motors empower companies to achieve these goals by offering reliable, energy-efficient solutions that meet the demands of modern operations.

Nanjing XYC: Your Trusted Supplier of WEG High Voltage Motors

At Nanjing XYC, we are committed to supplying cutting-edge solutions that drive efficiency and sustainability in the oil and gas sector. As a key supplier of WEG high voltage motors, we provide tailored solutions designed to meet your specific needs. Contact our experts today to learn how WEG motors can transform your operations, reduce costs, and enhance energy efficiency. Let us help you power the future of your business.

WEG High Voltage Electric Motors: Powering Industrial Efficiency

In today’s industrial landscape, reliable and energy-efficient electric motors are essential for optimizing operations and ensuring seamless production. WEG –…