Industrial systems demand precision, reliability, and efficiency to operate effectively. In critical applications such as chemical processing, water management, power generation, and oil and gas, valves play a pivotal role in controlling the flow of liquids, gases, and other materials. KSB valves are designed to meet these demands, offering exceptional performance and optimization capabilities for industrial systems.

Why Valve Optimization Matters

Valve performance has a direct impact on the overall efficiency, safety, and cost-effectiveness of an industrial system. Optimizing valve selection and usage ensures:

• Enhanced flow control, reducing energy consumption.

• Improved system reliability, minimizing downtime.

• Extended equipment life, cutting maintenance costs.

KSB valves are renowned for their advanced engineering, making them the perfect choice for achieving these optimization goals.

Key Features of KSB Valves

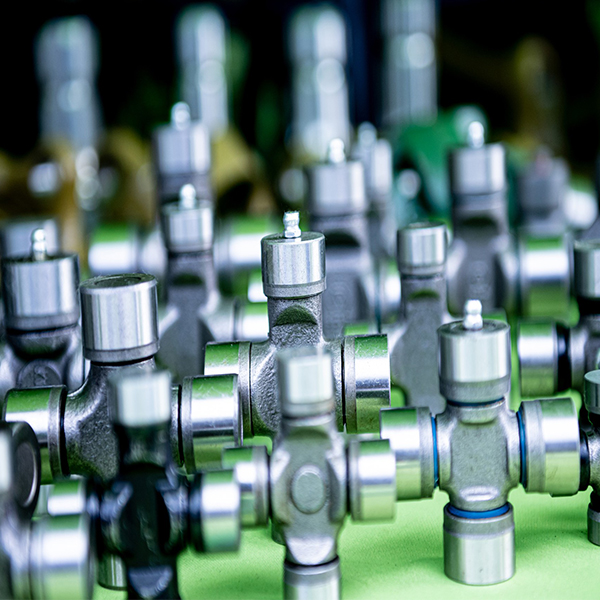

1. Precision Engineering

KSB valves are manufactured with cutting-edge technology, ensuring precise flow regulation. This precision helps to prevent leaks, maintain system balance, and improve operational efficiency.

2. Material Versatility

KSB valves are available in a wide range of materials, including stainless steel, cast iron, and specialty alloys. This versatility allows them to handle corrosive, high-pressure, and high-temperature environments, making them ideal for diverse industrial applications.

3. Energy Efficiency

With designs that minimize pressure drops and optimize flow paths, KSB valves help industrial systems reduce energy consumption. This translates to lower operational costs and a reduced carbon footprint.

4. Automation and Integration

Modern KSB valves can be integrated into automated control systems, allowing for real-time monitoring and adjustments. This level of automation enhances system performance and reduces the need for manual intervention.

Steps to Optimize Your System with KSB Valves

1. Assess System Requirements

Evaluate your system’s specific needs, including flow rate, pressure, temperature, and the nature of the media being handled.

2. Choose the Right Valve Type

KSB offers a wide range of valve types, including butterfly, globe, gate, and ball valves. Each type is suited to specific functions, such as throttling or isolation.

3. Consider Material Compatibility

Select valve materials that can withstand the chemical and physical properties of the media. This ensures durability and prevents system failure.

4. Leverage Expert Support

Work with experts to determine the ideal valve configurations and installation practices for your system. Proper guidance ensures optimal valve performance and long-term benefits.

5. Maintain and Monitor

Regular maintenance and real-time monitoring using automated systems help to maintain valve efficiency and detect issues early, preventing costly breakdowns.

Applications Across Industries

KSB valves are trusted in industries ranging from wastewater treatment to petrochemicals, where precision and durability are paramount. Their ability to handle complex requirements ensures seamless operation in even the most challenging environments.

Why Choose KSB for System Optimization?

With decades of experience and a reputation for quality, KSB valves deliver unmatched performance and reliability. Their innovative designs and comprehensive product range make them a leader in industrial flow control solutions.

Partner with Nanjing XYC for Your KSB Valve Needs

As a trusted supplier of KSB valves, Nanjing XYC is dedicated to helping you optimize your industrial systems. Our team of experts will guide you in selecting the perfect valve solutions for your specific needs. Contact Nanjing XYC today to explore our extensive product range and experience unparalleled support for your industrial operations.

Best Practices for Maintaining KSB Valves in Extreme Environments

In the world of industrial engineering, where precision, reliability, and safety are non-negotiable, the performance of pumps and valves often…