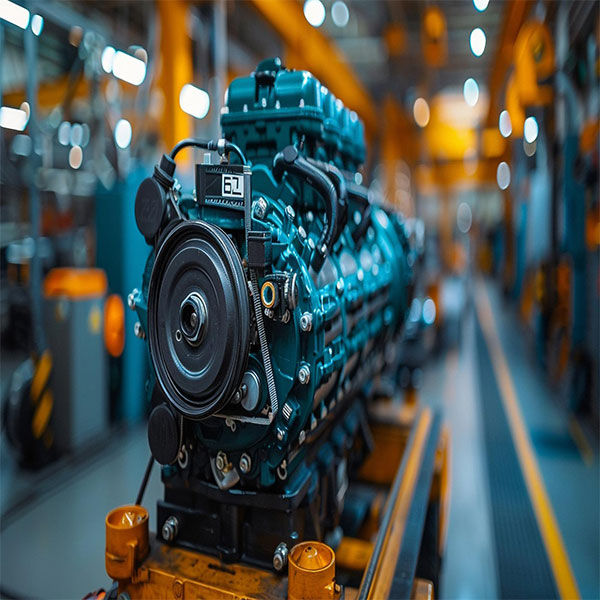

In power plants, system efficiency is paramount to ensure continuous, reliable, and cost-effective electricity generation. One of the key components driving efficiency in modern power plants is the high voltage motor. WEG high voltage motors are renowned for their exceptional performance, energy efficiency, and reliability, making them an ideal choice for power plants looking to enhance operational productivity and reduce energy consumption. These motors play a crucial role in driving various mechanical systems and processes in power plants, from pumping and ventilation to compression and grinding, all of which contribute significantly to plant efficiency.

1. High Energy Efficiency for Reduced Operating Costs

Power plants are energy-intensive operations, and energy costs are a significant part of the operational budget. WEG high voltage motors are engineered to deliver exceptional energy efficiency. These motors use advanced design technologies and materials that minimize energy loss, ensuring that more of the electrical power is converted into mechanical energy. This increased energy efficiency directly translates to reduced electricity consumption, leading to lower operational costs and a more sustainable power plant.

2. Enhanced Performance in Demanding Applications

In power plants, motors must operate under varying loads and demanding conditions. WEG high voltage motors are designed to perform optimally in such environments, delivering reliable and consistent performance. Whether powering large pumps, fans, compressors, or crushers, these motors are built to handle high torque loads and maintain stable performance even under fluctuating operational conditions. Their robustness and durability ensure that power plants can operate continuously without unexpected downtime, improving overall plant productivity.

3. Extended Lifespan and Reduced Maintenance Costs

Downtime and maintenance are critical concerns for any power plant, as they can result in significant losses in productivity and increased repair costs. WEG high voltage motors are constructed with high-quality materials that extend the lifespan of the motor, reducing the frequency of replacements and repairs. Moreover, these motors are designed with features that simplify maintenance, such as easy-to-access components and advanced cooling systems that help maintain optimal motor temperatures. This not only improves the reliability of the plant’s operations but also reduces maintenance costs over time.

4. Adaptability for Diverse Power Plant Applications

Power plants vary widely in size and application, and as such, their motor requirements can differ significantly. WEG high voltage motors are highly adaptable and can be tailored to meet the specific needs of different power plant configurations. These motors can be customized for various applications, including power generation, water circulation, cooling, and auxiliary systems. Their versatility ensures that they can be deployed in both traditional and renewable energy plants, offering consistent performance in all types of environments.

5. Compliance with Industry Standards and Environmental Regulations

Power plants operate in highly regulated environments, where strict compliance with industry standards and environmental regulations is crucial. WEG high voltage motors are designed to meet the highest global standards for safety, efficiency, and environmental performance. They adhere to various international certifications, ensuring that power plants can operate without compromising on quality or compliance. These motors also contribute to the reduction of carbon emissions, as their high efficiency minimizes the amount of energy required for operation, aligning with sustainability goals.

6. Smart Monitoring and Integration with Digital Systems

Modern power plants are increasingly incorporating digital technologies to enhance performance, optimize operations, and ensure predictive maintenance. WEG high voltage motors are compatible with smart monitoring systems that allow plant operators to remotely track the health of the motor, detect potential issues before they become critical, and optimize performance in real-time. This level of integration helps improve decision-making, minimize unplanned outages, and extend the life of the motor, further increasing the efficiency of the overall plant system.

Incorporating WEG high voltage motors into power plant systems can significantly enhance operational efficiency. Their high energy efficiency, robust performance, extended lifespan, and adaptability to various applications make them an essential component in modern power generation. By reducing energy consumption and minimizing downtime, these motors contribute to lower operational costs and increased productivity, ensuring that power plants can meet both economic and environmental goals.

Nanjing XYC: Your Trusted Supplier of WEG High Voltage Motors

Nanjing XYC operates as a key supplier of WEG high voltage motors, offering tailored solutions that enhance the efficiency and reliability of power plant operations. If you are looking to optimize your power plant systems and improve overall performance, contact Nanjing XYC experts today. Our team is ready to help you choose the best WEG motor solutions that meet your specific needs and ensure the smooth, efficient operation of your facility.

WEG High Voltage Electric Motors: Powering Industrial Efficiency

In today’s industrial landscape, reliable and energy-efficient electric motors are essential for optimizing operations and ensuring seamless production. WEG –…