In the demanding landscape of heavy industries, efficiency and reliability are essential for maintaining high productivity levels. Among the critical equipment supporting these operations, rotary screw compressors have emerged as indispensable tools. These compressors are renowned for their robust performance, energy efficiency, and adaptability to various industrial environments. This article delves into the mechanisms of rotary screw compressors and their pivotal role in heavy industries.

Understanding Rotary Screw Compressors

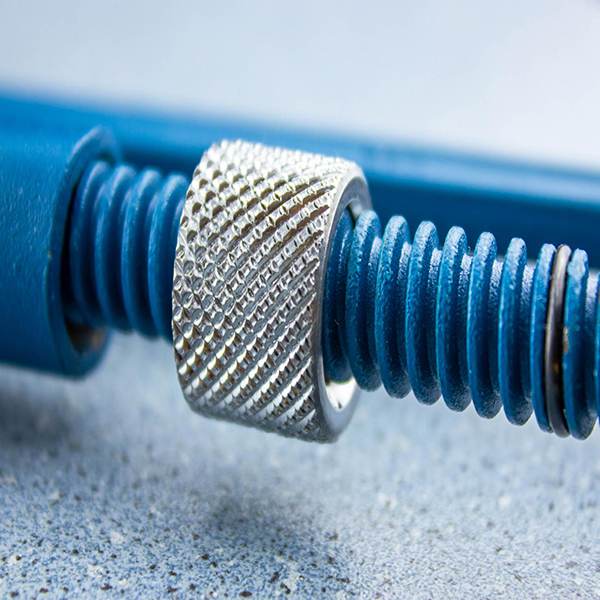

Rotary screw compressors operate on a simple yet highly efficient principle of air compression. The core mechanism involves two interlocking helical rotors—male and female screws—that rotate within a sealed chamber. As the rotors turn, they reduce the volume of air trapped between them, compressing it and delivering a steady stream of pressurized air.

Unlike piston compressors, rotary screw compressors offer continuous operation with minimal pulsation, making them ideal for applications requiring a constant air supply. Their design minimizes vibration, ensuring durability and quiet operation even under intensive industrial use.

Key Features of Rotary Screw Compressors

1. High Efficiency:

Rotary screw compressors are engineered for optimal energy efficiency, reducing operational costs while maintaining high output levels. Advanced designs, such as variable speed drives (VSD), further enhance efficiency by adjusting the compressor’s speed to match air demand.

2. Reliability:

Heavy industries demand equipment that can withstand rigorous conditions. Rotary screw compressors are built with high-quality materials and precision engineering, ensuring consistent performance and reduced maintenance requirements.

3. Compact Design:

Despite their powerful capabilities, rotary screw compressors are relatively compact, making them easy to integrate into industrial setups with space constraints.

4. Low Noise and Vibration:

The smooth operation of rotary screw compressors results in reduced noise levels and minimal vibration, enhancing workplace safety and comfort.

Applications in Heavy Industries

Rotary screw compressors play a vital role across numerous heavy industrial applications, including:

1. Mining and Excavation:

Compressed air is crucial for powering pneumatic tools, drills, and other equipment used in mining operations. Rotary screw compressors provide the reliability and power needed in these demanding environments.

2. Oil and Gas Exploration:

In oil and gas facilities, rotary screw compressors support tasks like gas compression, pipeline cleaning, and maintenance activities, ensuring seamless operations in critical systems.

3. Steel and Metal Fabrication:

The production of steel and other metals requires compressed air for cooling, blasting, and powering machinery. Rotary screw compressors deliver consistent airflow to support these intensive processes.

4. Chemical and Petrochemical Plants:

Compressed air is essential for transferring, mixing, and processing chemicals. Rotary screw compressors ensure the precision and reliability required in these highly regulated environments.

The Edge of Rotary Screw Compressors in Heavy Industries

Rotary screw compressors offer several advantages over traditional air compression technologies:

• Continuous Operation: They provide a steady flow of compressed air, ideal for industrial setups requiring uninterrupted operation.

• Energy Optimization: Advanced features, such as VSD and heat recovery systems, reduce energy consumption, aligning with sustainability goals.

• Long Lifespan: With proper maintenance, these compressors offer extended service life, ensuring a high return on investment.

Nanjing XYC: Your Reliable Partner in Atlas COPCO Compressors

As a key supplier of Atlas COPCO compressors, Nanjing XYC is committed to delivering high-performance solutions tailored to the demands of heavy industries. Whether you need advice on selecting the right compressor or require detailed technical support, our team of experts is ready to assist. Contact Nanjing XYC today to discover how our compressors can optimize your industrial operations.