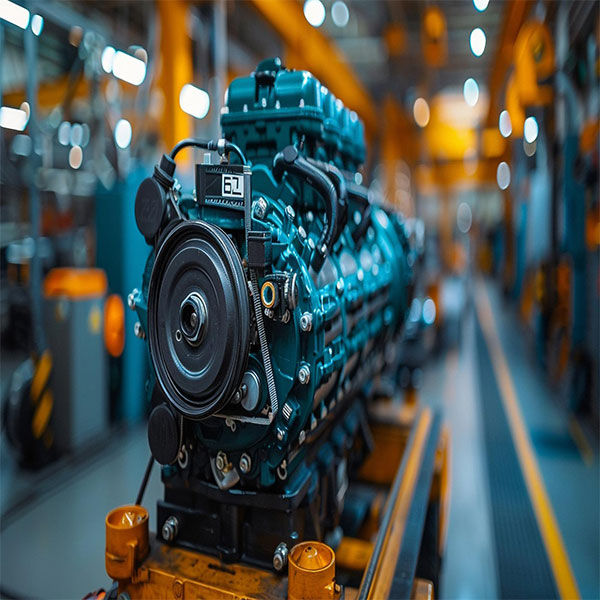

The textile industry is a cornerstone of global manufacturing, demanding equipment that is both reliable and energy-efficient. Among the critical components driving innovation and efficiency in this sector are WEG motors. Known for their advanced technology, robust performance, and energy-saving capabilities, WEG motors play an essential role in optimizing textile production processes. This article explores how WEG motors empower textile manufacturers to achieve peak performance while reducing operational costs.

The Demands of Textile Manufacturing

Textile manufacturing involves intricate and continuous processes such as spinning, weaving, dyeing, and finishing. These operations require precise control, high-speed performance, and sustained reliability to ensure product quality and cost efficiency. Motors are the backbone of these systems, driving key machinery like looms, dyeing vats, and conveyors.

However, the challenges of frequent start-stops, varying load demands, and high energy consumption can impact productivity and increase costs. WEG motors address these challenges with advanced designs tailored for the specific needs of textile manufacturing.

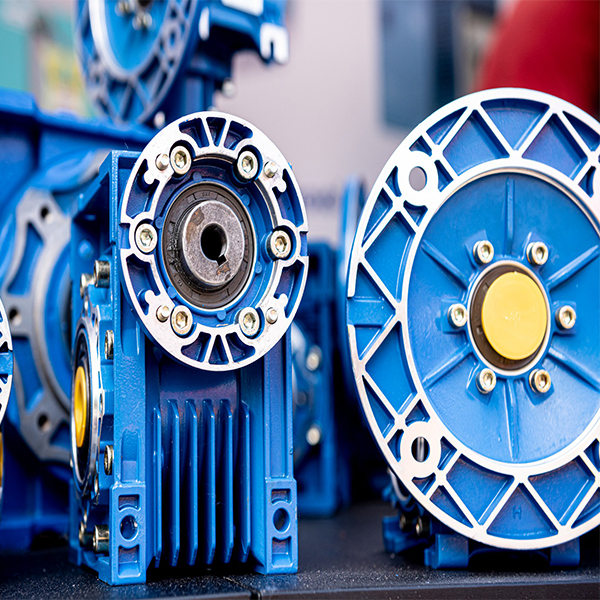

Key Features of WEG Motors for Textile Applications

1. High Energy Efficiency:

WEG motors comply with global energy efficiency standards, such as IE3 and IE4, reducing energy consumption and operational costs. This is particularly important in textile plants, where motors often run continuously.

2. Precision Control:

Integrated variable frequency drives (VFDs) in WEG motors enable precise speed and torque control, ensuring smooth operation across different textile processes.

3. Durability and Reliability:

Built with robust materials and state-of-the-art engineering, WEG motors are designed to withstand the demanding conditions of textile production, including high humidity, heat, and continuous operation.

4. Compact and Lightweight Design:

WEG motors feature compact designs, making them easy to integrate into existing textile machinery without requiring significant modifications.

5. Reduced Noise and Vibration:

The smooth operation of WEG motors minimizes noise and vibration, contributing to a safer and more comfortable working environment.

Applications of WEG Motors in Textile Manufacturing

1. Spinning:

In spinning operations, WEG motors ensure consistent performance in driving spindles and roving frames. Their precision control allows manufacturers to maintain uniform yarn quality.

2. Weaving:

Weaving machines, such as looms, rely on high-speed motors for efficient operation. WEG motors provide the necessary torque and speed control, reducing wear and tear on the machinery.

3. Dyeing and Finishing:

Processes like dyeing, drying, and finishing require precise temperature and speed adjustments. WEG motors with VFDs enable accurate control, enhancing the quality of finished fabrics.

4. Material Handling:

From raw material transportation to finished product packaging, WEG motors power conveyors and other handling equipment, ensuring smooth workflow throughout the production line.

Advantages of Using WEG Motors in the Textile Industry

• Energy Savings: Reduced electricity bills due to high energy efficiency.

• Enhanced Productivity: Minimized downtime and improved process consistency.

• Eco-Friendly Operation: Compliance with environmental regulations through reduced energy consumption.

• Longevity: Extended motor lifespan reduces replacement frequency and maintenance costs.

Partner with Nanjing XYC for WEG Motor Solutions

As a trusted supplier of WEG motors, Nanjing XYC is dedicated to supporting the textile industry with cutting-edge motor technology. Whether you are upgrading existing machinery or designing a new production line, our experts can provide tailored solutions to maximize your operational efficiency. Contact Nanjing XYC today to learn more about our products and how we can help transform your textile manufacturing processes.

WEG High Voltage Electric Motors: Powering Industrial Efficiency

In today’s industrial landscape, reliable and energy-efficient electric motors are essential for optimizing operations and ensuring seamless production. WEG –…