In industrial and commercial environments, noise pollution has become a growing concern due to its impact on worker health, operational efficiency, and environmental compliance. With the rising demand for quieter machinery, Atlas Copco has pioneered innovative technologies that significantly reduce noise levels in their equipment, setting new industry standards.

The Challenge of Noise Pollution in Industry

High noise levels are common in industries such as manufacturing, construction, and power generation. Prolonged exposure to excessive noise can lead to:

• Hearing Loss: A critical occupational hazard for workers.

• Lower Productivity: Noise distractions can hinder concentration and efficiency.

• Regulatory Fines: Non-compliance with noise level standards can result in penalties.

• Environmental Impact: Excessive noise affects surrounding communities, straining relationships with local residents and authorities.

Reducing noise pollution is not just a regulatory requirement but also a commitment to improving workplace safety and environmental responsibility.

Atlas Copco’s Noise-Reduction Innovations

Atlas Copco has developed cutting-edge solutions to tackle noise pollution without compromising performance. These advancements are integrated across their range of compressors, generators, and industrial equipment.

1. Sound-Insulated Enclosures:

Many Atlas Copco machines are designed with advanced soundproof enclosures. These enclosures absorb and minimize sound waves, significantly reducing the noise emitted during operations.

2. Optimized Airflow Systems:

Noise generated by air compressors often comes from turbulent airflow. Atlas Copco addresses this with aerodynamic designs that streamline airflow, cutting down turbulence and the associated noise.

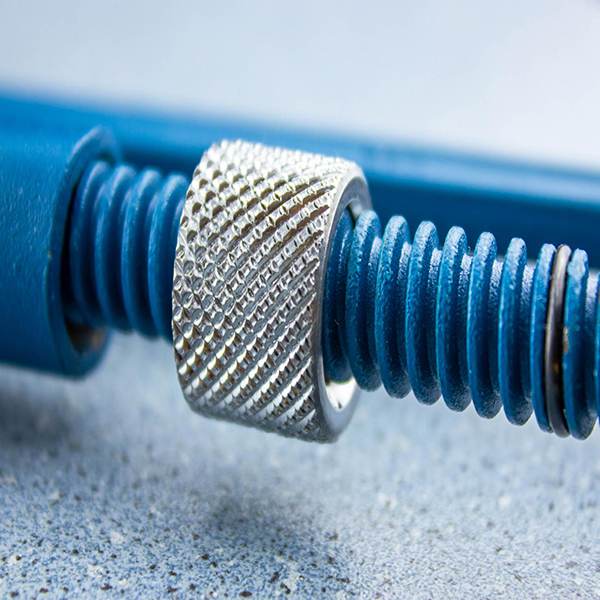

3. Vibration Dampening Technology:

Excessive noise often originates from mechanical vibrations. Atlas Copco employs vibration-isolating mounts and dampening materials in their equipment to minimize vibration and its impact on sound levels.

4. Variable Speed Drives (VSD):

Atlas Copco’s VSD technology optimizes motor speed based on demand, reducing the noise typically produced during high-speed operation. This not only lowers noise levels but also enhances energy efficiency.

5. Quiet Air Filters and Mufflers:

Specialized air filters and mufflers are integrated into their systems to absorb and reduce the noise from air intake and exhaust processes.

Applications Benefiting from Atlas Copco’s Low-Noise Technologies

Atlas Copco’s noise-reduction advancements have wide-ranging applications:

• Construction Sites: Quieter equipment enhances compliance with urban noise regulations and minimizes disruption to surrounding areas.

• Manufacturing Plants: Low-noise machinery improves worker comfort and safety, boosting productivity.

• Hospitals and Research Facilities: Quiet air compressors and vacuum systems are ideal for noise-sensitive environments.

• Urban Infrastructure Projects: Reduced noise levels make Atlas Copco equipment suitable for use in densely populated areas.

Benefits of Choosing Atlas Copco for Noise-Reduction Solutions

By choosing Atlas Copco’s low-noise technologies, businesses can:

• Enhance workplace safety and worker well-being.

• Improve community relations by minimizing noise disturbances.

• Achieve compliance with local and international noise regulations.

• Maintain high performance and efficiency without the drawbacks of excessive noise.

Partner with Nanjing XYC for Atlas Copco Solutions

Nanjing XYC is proud to be a trusted supplier of Atlas Copco equipment, including their noise-reducing technologies. With a commitment to delivering innovative solutions, we help businesses improve operational efficiency while addressing noise pollution challenges. Contact our experts today to learn how Atlas Copco’s advanced technologies can transform your operations. Let us guide you to quieter, more efficient industrial solutions.

Energy Efficiency Innovations by Atlas Copco That Save You Money

In today’s highly competitive industrial landscape, operational efficiency and energy savings are key priorities for manufacturers, power plants, and oil…