Valves play a critical role in ensuring the efficiency, reliability, and safety of industrial processes. When selecting valves, businesses face the challenge of navigating a wide range of brands and models, each promising superior performance. Among the global leaders in this field, KSB valves have set a benchmark for quality and innovation. This article explores how KSB valves stand apart from competitor products, highlighting their unique features and advantages for industrial applications.

Key Features of KSB Valves

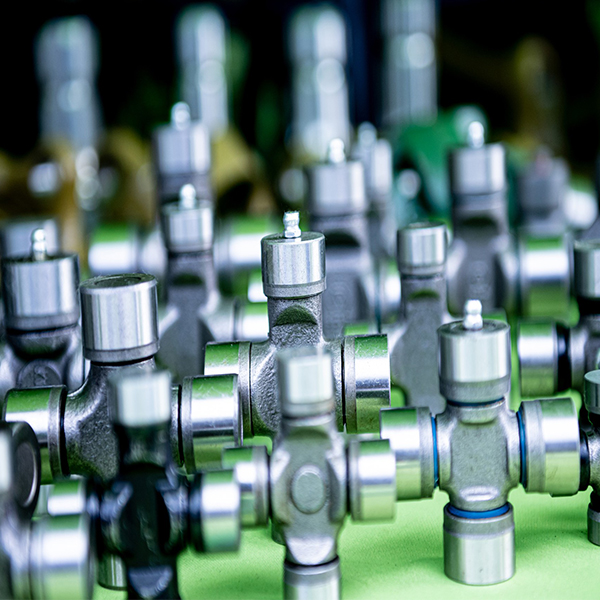

- Precision Engineering:

KSB valves are designed with meticulous attention to detail, ensuring precise control of flow, pressure, and temperature in complex industrial environments. - Robust Construction:

Using advanced materials such as high-grade alloys and innovative coatings, KSB valves are built to withstand extreme conditions, including high pressure, high temperature, and corrosive media. - Energy Efficiency:

With low operational torque and optimized flow paths, KSB valves contribute to energy savings, an increasingly critical factor for industries aiming to reduce operational costs and environmental impact. - Customization Options:

KSB offers a wide range of valve types and custom configurations, allowing businesses to tailor solutions to their unique process requirements.

Advantages Over Competitor Products

- Durability and Longevity

While many competitor products meet baseline industry standards, KSB valves exceed these by offering enhanced durability. Their robust designs lead to longer service life, reducing the need for frequent replacements and minimizing downtime.

- Superior Sealing Technology

KSB valves feature advanced sealing mechanisms that provide exceptional leak prevention, even in high-pressure or high-temperature systems. This ensures safety and operational efficiency across diverse applications.

- Global Support Network

Unlike many competitors, KSB offers comprehensive global support, including technical assistance, maintenance services, and quick access to spare parts, ensuring uninterrupted operations.

- Sustainability-Focused Design

Competitors often lag behind in sustainability. KSB valves are designed with eco-friendly manufacturing processes and materials, aligning with modern industry goals of reducing carbon footprints.

- Testing and Certification

Each KSB valve undergoes rigorous testing to meet international certifications, such as ISO and API standards, ensuring unmatched reliability and performance compared to many generic brands.

Industry Applications

KSB valves are used across various industries, including:

- Oil and Gas: Precise control in high-pressure pipelines and refineries.

- Power Generation: Reliability in critical systems such as steam turbines and cooling circuits.

- Chemical Processing: Resistance to aggressive chemicals and extreme conditions.

- Water Treatment: Effective flow management in filtration and wastewater systems.

Making the Right Choice

When comparing valves, it’s essential to evaluate not only the upfront cost but also long-term performance, maintenance requirements, and operational efficiency. While competitor products may offer lower initial prices, the superior engineering, reliability, and sustainability of KSB valves provide better value over time.

KSB valves represent a premium choice for industries seeking precision, durability, and cost efficiency. Their ability to outperform competitors in critical areas like sealing, durability, and energy efficiency makes them an investment in long-term operational excellence.

Nanjing XYC is proud to be a trusted supplier of KSB valves, offering expert guidance and top-notch customer support. Contact Nanjing XYC today to learn more about how KSB valves can elevate your industrial processes.