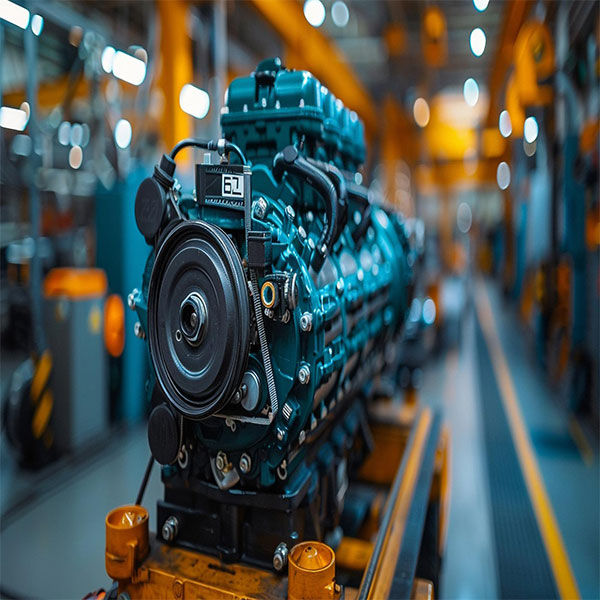

The pulp and paper industry relies on highly specialized equipment to transform raw materials into finished products. From the initial stages of pulping to the final production of paper, the machinery involved requires motors that are both reliable and efficient. WEG motors are a top choice for this industry, offering robust performance that meets the rigorous demands of pulp and paper production processes. Their versatility, efficiency, and durability make them a preferred solution for a wide range of applications within the sector.

Key Applications of WEG Motors in the Pulp and Paper Industry

In the pulp and paper industry, the machinery used operates in tough conditions, often running 24/7 in high-load environments. Motors in these systems are critical to ensure smooth operation and high efficiency. WEG motors offer advanced solutions for several key applications within this sector.

- Pulping Process

The pulping process is one of the most energy-intensive stages of paper production. It involves the breakdown of raw materials like wood chips into a slurry of cellulose fibers. WEG motors are widely used to power pulping machinery, including grinders, refiners, and digesters. These motors are engineered to provide consistent power and withstand the mechanical stresses of high-load operations.

- Energy Efficiency: WEG motors help reduce energy consumption in the pulping process, lowering operational costs.

- Robust Design: These motors are built to handle the high loads and continuous duty cycles typical of pulping operations, ensuring longevity and reliability.

- Paper Mill Machinery

From the initial sheet formation to the final drying process, paper mills depend on various machines such as pressers, dryers, and calenders to produce paper efficiently. WEG motors are essential for driving these machines, ensuring consistent speed and precision throughout the paper production line. Their high-performance capabilities help maintain optimal production rates while minimizing downtime.

- Precision Control: WEG motors offer precise control over machine speed, contributing to better paper quality and uniformity.

- Reduced Downtime: With their long operational lifespan and high reliability, WEG motors minimize the frequency of breakdowns, which is critical for maintaining continuous production in paper mills.

- Pulping and Paper Drying Equipment

Drying is another essential step in pulp and paper production. This stage requires a significant amount of energy, especially in large-scale mills where vast amounts of paper must be dried quickly and evenly. WEG motors power the fans, pumps, and compressors that are used in the drying systems. These motors offer superior efficiency, ensuring that the drying process is completed without wasting energy or resources.

- High Efficiency: WEG motors optimize the drying process, helping to reduce energy costs.

- Stable Operation: The motors are designed to work continuously in high-demand applications, maintaining stable performance under various load conditions.

- Conveyor Systems

Conveyor systems are crucial for transporting raw materials, pulp, and finished paper products throughout the mill. WEG motors are often used in these systems to drive the conveyors. With their powerful performance and energy-efficient design, WEG motors ensure smooth, continuous material flow, enhancing the overall efficiency of the production process.

- Durability: WEG motors are designed to withstand the harsh conditions of the pulp and paper industry, ensuring long-lasting performance even under heavy loads.

- Low Maintenance: Their high reliability reduces the need for frequent maintenance, allowing for smooth, uninterrupted operation of conveyor systems.

- Water and Wastewater Treatment Systems

Water is a critical resource in pulp and paper mills, used throughout the production process for cleaning, cooling, and treatment. WEG motors are essential for powering pumps and other water management systems that treat, recycle, and manage water waste. These motors are built to handle the high demands of water systems in pulp and paper plants, ensuring consistent operation and improved water conservation efforts.

- Sustainability: WEG motors help improve the efficiency of water usage in pulp and paper mills, contributing to better environmental practices.

- Reliable Pumping: With their superior durability and energy efficiency, WEG motors optimize pumping operations, reducing water and energy waste.

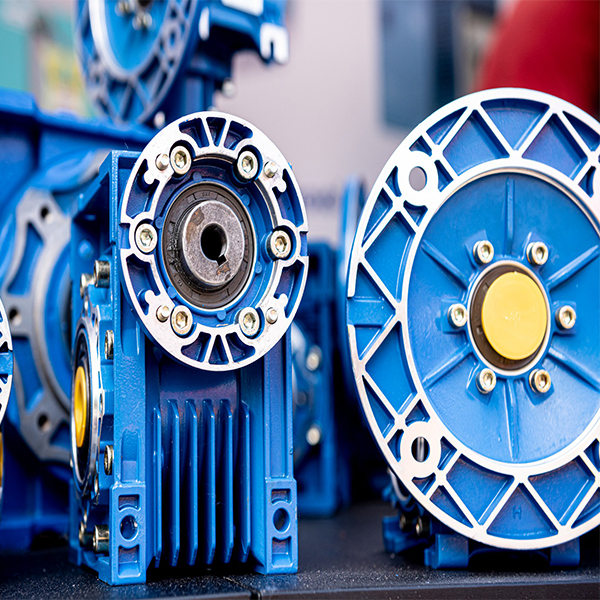

Benefits of WEG Motors in Pulp and Paper Operations

The unique design and engineering of WEG motors offer several advantages for the pulp and paper industry:

- Energy Efficiency: WEG motors are designed to reduce energy consumption, resulting in significant cost savings over time. Their high efficiency is crucial in reducing the energy-intensive operations typical in pulp and paper production.

- High Durability: The demanding environment of the pulp and paper industry requires equipment that can handle high mechanical stresses. WEG motors are engineered to withstand such conditions, providing long-lasting performance and reducing maintenance costs.

- Continuous Operation: These motors are designed for continuous duty applications, ensuring the smooth operation of pulp and paper production without the risk of failure, even under heavy loads.

- Custom Solutions: WEG offers customizable motor options, allowing companies to tailor the motors to their specific needs in terms of size, voltage, and power output.

WEG motors provide the reliability, energy efficiency, and durability required to meet the challenges of the pulp and paper industry. From pulping to drying and wastewater treatment, these motors help improve performance and reduce operational costs, ensuring optimal production at every stage of the process. By investing in WEG motors, pulp and paper manufacturers can enhance efficiency, minimize downtime, and achieve better sustainability in their operations.

Nanjing XYC is a key supplier of WEG motors for the pulp and paper industry. Contact Nanjing XYC experts today for more information on how WEG motors can improve the efficiency and performance of your operations.