Efficient fluid control is essential for optimizing industrial processes, ensuring safety, and minimizing operational costs. Industries dealing with complex fluid systems—whether in oil and gas, chemical processing, or water management—require reliable, high-performance valves to handle diverse challenges. KSB valve technologies have emerged as an industry leader in delivering cutting-edge solutions for fluid control. This article explores how KSB valves improve fluid management in industrial settings through innovation, precision, and reliability.

Key Innovations in KSB Valve Technologies

- Advanced Flow Dynamics

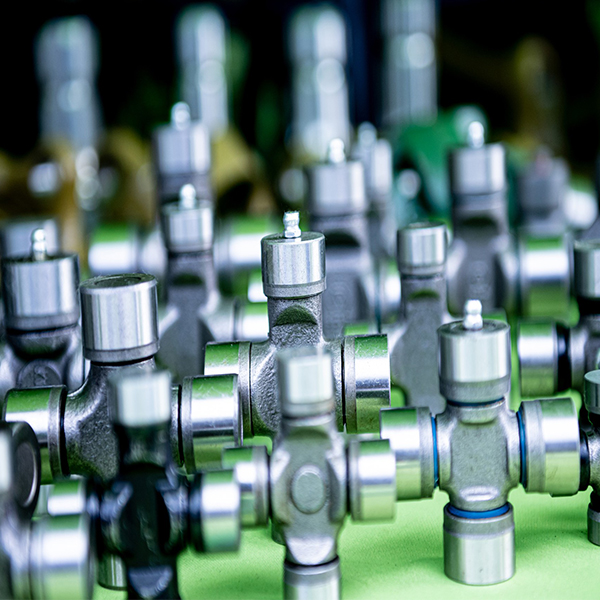

KSB valves are designed to minimize turbulence and ensure smooth flow, even in high-pressure or high-viscosity systems. Computational fluid dynamics (CFD) modeling guides the development of valve designs that maximize efficiency. - State-of-the-Art Materials

KSB employs corrosion-resistant alloys, composite materials, and advanced coatings to enhance durability and reliability. These materials ensure optimal performance, even in aggressive chemical environments. - Smart Valve Integration

Incorporating smart technology, KSB valves can be integrated with digital control systems, enabling real-time monitoring and precise adjustment of flow rates. This capability supports predictive maintenance and reduces downtime. - Specialized Sealing Systems

The unique sealing technologies in KSB valves, such as triple-offset designs and high-performance elastomers, ensure leak-free operation over extended periods, even under extreme conditions.

Benefits of KSB Valve Technologies in Industrial Applications

- Enhanced Process Efficiency

KSB valves ensure consistent flow control, reducing energy waste and enhancing the overall efficiency of fluid systems. Their precision allows operators to maintain optimal operating conditions with minimal adjustments.

- Cost Savings Through Longevity

The robust construction of KSB valves significantly reduces wear and tear, lowering maintenance costs and extending product lifecycles compared to standard valves.

- Safety and Reliability

In industries where safety is paramount, such as petrochemical processing or power generation, KSB valves provide unmatched reliability. They are engineered to prevent failures, leaks, and operational hazards.

- Versatility Across Applications

From handling corrosive chemicals to managing high-temperature steam, KSB valves are designed to meet the needs of diverse industries, making them a go-to solution for complex fluid control challenges.

- Sustainability-Focused Design

KSB’s focus on sustainability includes energy-efficient designs and eco-friendly materials, helping industries meet their environmental compliance goals while optimizing performance.

Applications of KSB Valve Technologies

- Oil and Gas: High-pressure pipelines, gas processing, and refinery operations.

- Chemical and Pharmaceutical: Handling corrosive, abrasive, or hazardous fluids with precision.

- Water and Wastewater Management: Regulating flow in filtration systems, desalination plants, and wastewater treatment facilities.

- Power Generation: Maintaining steam and cooling systems for improved efficiency.

KSB valve technologies represent the pinnacle of industrial fluid control, combining precision engineering, durability, and smart integration. Their ability to optimize processes, reduce costs, and ensure safety makes them an invaluable asset for industries worldwide.

Nanjing XYC proudly offers a comprehensive range of KSB valves tailored to meet your industrial requirements. For expert guidance and reliable supply, contact Nanjing XYC today and let our team help you enhance your fluid control systems.