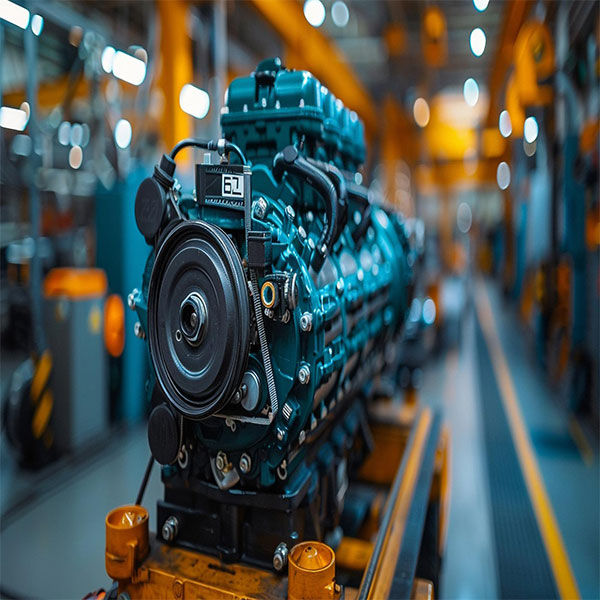

In today’s competitive industrial landscape, reducing energy consumption is a key focus for manufacturers and plant operators looking to optimize operational costs and improve environmental sustainability. One of the most effective ways to achieve this goal is by using energy-efficient motors, and WEG motors stand out as a top choice in this regard. These advanced motors are designed to help industries significantly reduce their energy consumption while maintaining high-performance standards across various applications.

The Importance of Energy Efficiency in Industrial Operations

Energy costs can constitute a significant portion of operational expenses, particularly in energy-intensive industries like manufacturing, mining, water treatment, and paper production. As global sustainability regulations become stricter and energy prices continue to rise, industries must adopt energy-saving technologies to stay competitive. Using energy-efficient motors is one of the most impactful ways to reduce consumption and operational costs.

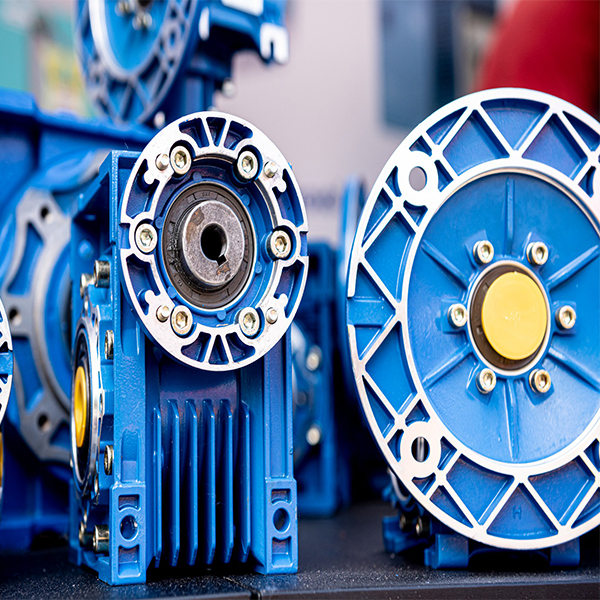

WEG motors are engineered with cutting-edge technology to minimize energy waste, making them a valuable investment for any industrial operation. Their efficiency does not compromise power output, ensuring that machines and equipment continue to perform optimally without drawing excessive power.

How WEG Motors Contribute to Energy Efficiency

- High-Efficiency Design

WEG motors are specifically designed with high-efficiency ratings, often surpassing the industry standards for energy consumption. They achieve this through advanced engineering that ensures the motors operate with minimal energy loss. By choosing WEG motors, businesses can reduce their overall energy usage without sacrificing the reliability and performance of their systems.

- Premium Efficiency Standards: WEG motors meet or exceed premium efficiency classes, such as the IE3 and IE4 standards, ensuring they deliver exceptional energy performance.

- Optimized Power Usage: These motors are built to consume the precise amount of energy required for optimal operation, reducing unnecessary power consumption during operation.

- Variable Speed Drives (VSD) Compatibility

One of the key factors in reducing energy consumption in industrial systems is the ability to adjust motor speed according to operational requirements. WEG motors can be paired with Variable Speed Drives (VSD), which allow operators to modify the motor speed based on real-time demands. This ability to adjust motor performance ensures that the motor consumes only the energy required, avoiding the energy waste associated with running at full capacity when it’s unnecessary.

- Energy Savings: By adjusting motor speed to the required load, industries can save up to 50% of the energy used in variable load applications.

- Smooth Operation: VSDs ensure that motors operate smoothly without abrupt changes in speed, enhancing both energy efficiency and equipment lifespan.

- Reduced Heat Generation

Efficient motors generate less heat, reducing the need for additional cooling systems. This translates into lower energy consumption overall, as less energy is needed for cooling equipment. WEG motors are designed to minimize heat production during operation, resulting in less strain on both the motor and the cooling infrastructure.

- Longer Equipment Life: Reduced heat means that the motor components experience less thermal stress, leading to fewer breakdowns and longer lifespans for both the motor and auxiliary equipment.

- Lower Cooling Costs: The reduction in heat generation decreases the reliance on energy-intensive cooling systems, further enhancing energy savings.

- Reduced Maintenance and Downtime

Efficient motors typically require less maintenance and have longer operational lifespans compared to conventional motors. Since WEG motors are built for durability and energy efficiency, they operate at lower stress levels and experience fewer failures. This results in reduced downtime and maintenance costs, contributing to overall energy savings by avoiding the energy expenditure associated with equipment repairs and replacements.

- Reliable Operation: With fewer breakdowns, production lines experience fewer interruptions, optimizing the overall energy usage.

- Lower Repair Costs: As these motors are designed for longevity, the need for costly repairs is minimized, further reducing operational expenses.

Industries Benefiting from WEG Motor Energy Savings

WEG motors are applicable across a wide range of industries that are energy-intensive, and the benefits of reducing energy consumption extend to sectors such as:

- Manufacturing: In sectors like automotive, steel, and plastics, where motors power machinery, reducing energy consumption can translate into substantial savings.

- Water Treatment: Energy-efficient motors in pumps, compressors, and other systems reduce power usage while maintaining performance, making water treatment plants more sustainable.

- Oil and Gas: In this high-power-demand sector, WEG motors optimize energy use in drilling, refining, and transportation systems.

- Mining: Energy-efficient motors ensure that mining operations can run continuously without excessive power consumption, even in harsh environments.

By reducing energy costs across these applications, WEG motors help businesses lower their carbon footprints and increase profitability.

WEG motors are a crucial component in the quest for energy efficiency in industrial operations. Their high-performance capabilities, combined with advanced energy-saving features, enable industries to reduce energy consumption, lower operational costs, and improve sustainability. By utilizing WEG motors, businesses can ensure reliable operation while making significant strides in energy conservation.

Nanjing XYC is a key supplier of WEG motors. For more information on how WEG motors can help reduce your energy consumption and enhance operational efficiency, contact Nanjing XYC experts today.