Powering the Future of Industrial Applications

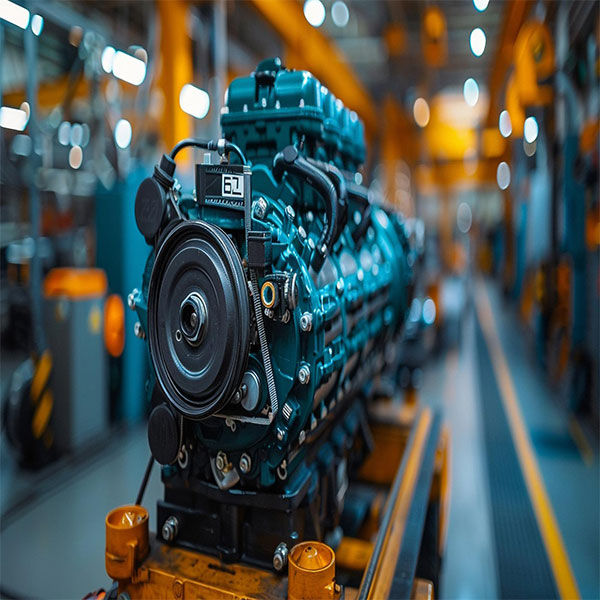

In today’s fast-paced industrial world, efficiency, reliability, and sustainability are top priorities for businesses looking to optimize operations. Industries such as manufacturing, power generation, oil & gas, mining, and heavy industries rely on robust, high-performance motors to drive critical processes.

WEG High Voltage Motors, available through Nanjing XYC, provide the power, durability, and energy efficiency that industrial applications demand. Whether it’s running compressors in oil refineries, driving turbines in power plants, or optimizing conveyor systems in mining operations, these motors deliver superior performance while minimizing downtime and maintenance costs.

In this article, we’ll explore the key features, industrial applications, competitive advantages, and technical insights that make WEG High Voltage Motors the ideal choice for industrial decision-makers.

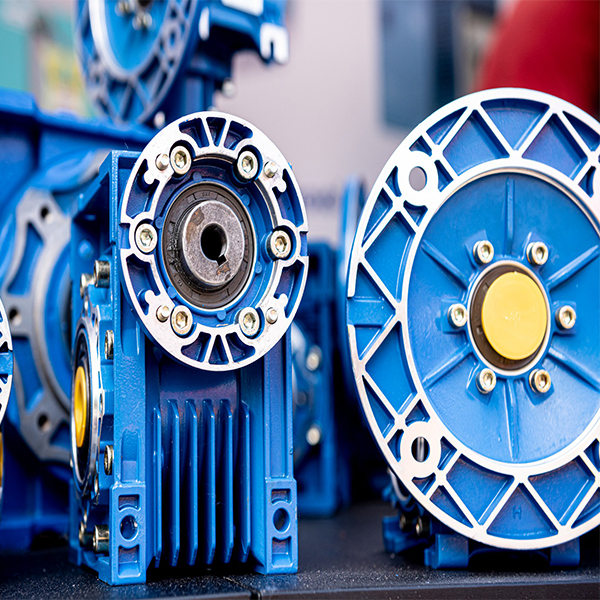

Key Features of WEG High Voltage Motors

WEG High Voltage Motors are engineered for the most demanding environments, offering:

High Efficiency and Energy Savings – These motors utilize advanced materials and precision engineering to minimize energy consumption, leading to significant cost savings in the long run.

Robust Construction for Harsh Environments – Built to withstand extreme temperatures, heavy loads, and corrosive conditions, WEG motors excel in industries where reliability is non-negotiable.

Versatile Power Ranges and Configurations – Available in various voltage and power ratings, these motors can be customized to fit diverse industrial needs, from small-scale production lines to large infrastructure projects.

Optimized Thermal Management – Efficient cooling mechanisms ensure prolonged motor lifespan and reduced risk of overheating, which is essential in high-demand applications.

Low Maintenance and High Durability – Designed with high-quality bearings, reinforced insulation systems, and advanced monitoring capabilities, these motors reduce the need for frequent maintenance, minimizing operational disruptions.

Industrial Applications: Where WEG High Voltage Motors Excel

- Manufacturing & Heavy Industry

In manufacturing plants, reliable motor performance is critical for running conveyors, extruders, crushers, and mixers. WEG motors provide the torque and speed control necessary for optimizing production efficiency while reducing energy costs.

- Power Generation

Power plants, including thermal, hydro, and renewable energy facilities, rely on high-voltage motors for driving turbines, pumps, and auxiliary equipment. WEG motors offer exceptional energy efficiency and load adaptability, ensuring consistent performance even under variable loads.

- Oil & Gas Sector

From drilling operations to refinery processing, WEG motors power compressors, pumps, and cooling systems in oil rigs and petrochemical plants. Their explosion-proof and corrosion-resistant designs make them ideal for offshore and onshore applications.

- Mining & Material Handling

Mines and material processing facilities use high-voltage motors to operate crushers, conveyors, hoists, and grinding mills. WEG motors provide high starting torque and overload capacity, essential for handling heavy loads in tough environments.

- Water & Wastewater Treatment

Municipal and industrial water treatment facilities need powerful motors for pumping, aeration, and filtration processes. WEG motors ensure reliable 24/7 operation, improving the efficiency of critical water infrastructure.

Competitive Advantages of WEG High Voltage Motors

When comparing WEG High Voltage Motors to other options in the market, several key advantages set them apart:

Superior Efficiency – WEG motors are designed with IE3 and IE4 energy efficiency standards, reducing operational costs over time.

Advanced Insulation and Cooling Systems – These motors utilize Vacuum Pressure Impregnation (VPI) insulation technology, enhancing their resistance to extreme environmental conditions.

Customizable Solutions – Unlike standard motors, WEG offers tailored configurations to meet specific industrial requirements, ensuring a perfect fit for every application.

Smart Monitoring & Predictive Maintenance – With IoT-enabled monitoring options, these motors allow for real-time diagnostics and predictive maintenance, helping businesses prevent costly downtime.

Global Compliance & Certification – WEG motors adhere to international quality and safety standards, including IEC, NEMA, and ATEX certifications, ensuring compliance across different industries.

Technical Insights: What Engineers and Procurement Specialists Need to Know

For engineers and industrial buyers, understanding the technical superiority of WEG High Voltage Motors is essential. Here’s what makes them a reliable choice:

- Voltage Ratings: Available in a wide range of voltages from 1.1kV to 13.8kV, accommodating different power requirements.

- Power Output: Designed to deliver from a few hundred kW to several megawatts, making them suitable for both standard and heavy-duty applications.

- Cooling Methods: Options include IC411 (self-ventilated), IC611 (forced ventilation), and IC81W (water-cooled systems), ensuring optimal thermal performance under different operating conditions.

- Protection Ratings: WEG motors come with IP55 and higher ingress protection ratings, offering superior resistance to dust, water, and contaminants.

- Bearings & Lubrication: Equipped with anti-friction bearings and automatic lubrication systems, reducing maintenance frequency and improving operational longevity.

Invest in WEG High Voltage Motors for Unmatched Performance

For industries looking to boost productivity, reduce downtime, and enhance energy efficiency, WEG High Voltage Motors stand out as the ultimate solution. Their superior design, advanced technology, and adaptability make them the preferred choice for industrial applications worldwide.

Ready to optimize your operations? Contact Nanjing XYC today to learn more about WEG High Voltage Motors, request a quote, or explore related industrial equipment.