Enhancing Efficiency and Reliability in Industrial Operations

In industries where fluid handling, energy efficiency, and system reliability are critical, selecting the right pumps and valves can make a substantial impact on operational efficiency, cost savings, and equipment longevity. KSB Pumps and Valves, available at Nanjing XYC, are designed to optimize industrial fluid management, reduce energy consumption, and ensure seamless operations across sectors such as power generation, oil & gas, water treatment, and manufacturing.

With cutting-edge engineering and innovative designs, KSB’s high-performance pumps and valves deliver exceptional reliability, efficiency, and durability, making them a preferred choice for industrial buyers, engineers, and decision-makers.

In this article, we explore the key features, industrial applications, competitive advantages, and technical insights of KSB Pumps and Valves, highlighting how they enhance power generation facilities and other industrial sectors.

Key Features of KSB Pumps and Valves

- Superior Hydraulic Efficiency

KSB pumps are designed with advanced hydraulic profiles that minimize energy losses and maximize efficiency, reducing operational costs while enhancing flow rate precision.

- Robust Construction for Long-Term Reliability

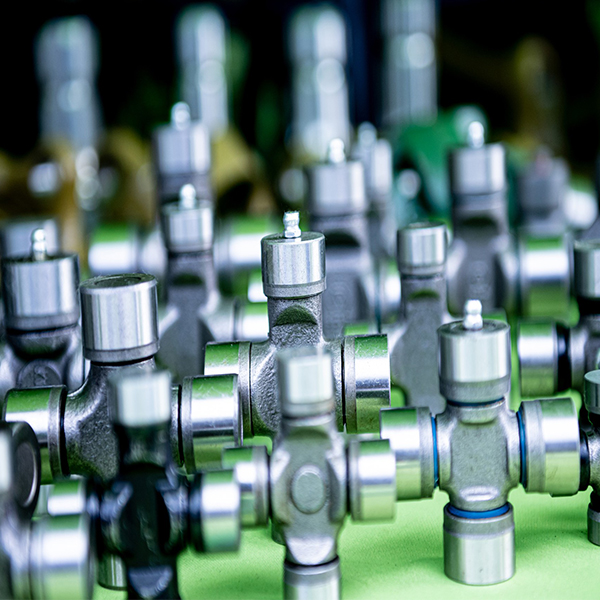

Manufactured from high-quality materials, KSB pumps and valves exhibit exceptional corrosion resistance, high pressure tolerance, and thermal stability, making them ideal for demanding industrial applications.

- Versatile Pumping Solutions

KSB offers a wide range of pumps, including centrifugal pumps, submersible pumps, and high-pressure pumps, catering to industries such as power plants, refineries, and chemical processing.

- Precision Engineered Valves

KSB’s industrial valves ensure seamless flow control, minimal pressure drops, and superior sealing performance, enhancing system reliability and safety.

- Low Maintenance and Reduced Downtime

With innovative wear-resistant materials and self-lubricating components, KSB pumps and valves require minimal maintenance, reducing unexpected failures and costly downtime.

Industrial Applications: Where KSB Pumps and Valves Excel

- Power Generation

In thermal power plants, boiler feed pumps, cooling water pumps, and condensate pumps play a vital role in maintaining efficient heat transfer and steam generation. KSB pumps provide high-pressure performance, energy efficiency, and low maintenance costs, ensuring uninterrupted power generation.

- Oil & Gas Industry

The oil & gas sector demands reliable fluid management solutions for crude oil transport, refining processes, and offshore drilling operations. KSB’s corrosion-resistant pumps and high-performance control valves optimize fluid flow, enhance operational safety, and reduce energy consumption.

- Water and Wastewater Treatment

Municipal and industrial water treatment plants rely on KSB’s submersible pumps and chemical dosing pumps for water circulation, filtration, and wastewater disposal. These pumps offer superior resistance to aggressive chemicals and high-efficiency fluid transfer.

- Chemical and Petrochemical Processing

The chemical industry requires pumps that handle abrasive, corrosive, and high-viscosity fluids. KSB’s specially designed pumps and anti-corrosion coated valves ensure safe chemical transport and precise process control.

- Mining and Heavy Industry

KSB’s slurry pumps are widely used in mining operations, where they transport abrasive materials such as ore, sand, and mineral concentrates. Their high wear resistance and robust design make them ideal for high-pressure pumping applications.

Competitive Advantages: Why Choose KSB Pumps and Valves?

When comparing KSB Pumps and Valves to other market alternatives, several key benefits stand out:

Technical Insights: What Engineers and Procurement Specialists Need to Know

For industrial professionals seeking precision fluid management solutions, here are key technical insights about KSB Pumps and Valves:

- Pump Efficiency Ratings: Up to 90% efficiency, reducing energy losses in large-scale industrial applications.

- Material Options: Available in cast iron, stainless steel, duplex alloys, and corrosion-resistant coatings for different fluid handling requirements.

- Pressure Handling Capacity: Ranges from low-pressure centrifugal pumps to high-pressure multistage pumps for complex fluid transport needs.

- Valve Configurations: Includes gate valves, butterfly valves, control valves, and check valves designed for optimized flow regulation and safety.

- Operating Temperature Range: Capable of handling extreme temperatures from -40°C to 400°C, making them suitable for thermal power plants, chemical refineries, and cryogenic systems.

Optimize Your Industrial Operations with KSB Pumps and Valves

For industries requiring reliable, energy-efficient, and durable fluid management solutions, KSB Pumps and Valves offer unmatched performance and cost savings. Whether in power generation, oil & gas, water treatment, or manufacturing, KSB products ensure optimal efficiency and system longevity.

Upgrade your industrial operations with KSB Pumps and Valves today!