In modern industrial operations, efficient cooling systems are critical to maintaining optimal performance, ensuring equipment longevity, and preventing costly downtime. KSB – Industrial Valves and Pumps play a vital role in managing industrial cooling systems by providing reliable, high-performance fluid handling solutions. Whether in manufacturing, power generation, or the oil & gas sector, KSB pumps are engineered to improve operational efficiency and tackle industry-specific challenges effectively.

Key Features of KSB Industrial Valves and Pumps

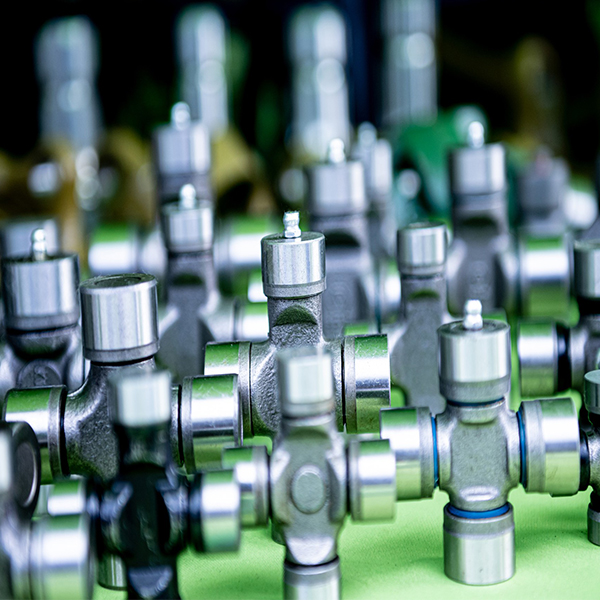

KSB’s industrial valves and pumps are designed with cutting-edge technology to ensure superior performance. Here are some of the key features that set them apart:

- High Efficiency: KSB pumps operate with minimal energy consumption, reducing operational costs while maximizing output.

- Robust Construction: Built from high-quality materials, these pumps and valves withstand extreme temperatures, high pressures, and corrosive environments.

- Precision Flow Control: KSB’s innovative valve technology ensures accurate fluid control, optimizing system performance in industrial applications.

- Low Maintenance Requirements: With durable components and advanced engineering, these pumps require less frequent servicing, minimizing downtime.

- Customizable Solutions: KSB offers a wide range of products tailored to meet specific industrial requirements, enhancing versatility and adaptability.

Industrial Applications of KSB Pumps

KSB pumps are widely used across various industries due to their reliability and efficiency. Here’s how they enhance key industrial processes:

- Manufacturing Industry

- Ensuring stable cooling for heavy machinery to prevent overheating.

- Providing precise fluid management in automated production lines.

- Power Generation

- Regulating cooling water circulation in thermal and nuclear power plants.

- Enhancing efficiency in heat exchange systems.

- Oil & Gas Sector

- Managing cooling systems in refining and petrochemical processes.

- Supporting offshore and onshore drilling operations with reliable fluid transport.

- Steel and Metal Processing

- Optimizing quenching and cooling processes in metal production.

- Reducing equipment wear and tear through stable fluid flow control.

Competitive Advantages of KSB Pumps

When compared to other industrial pumps in the market, KSB pumps offer several unique advantages:

- Superior Technology: Advanced engineering ensures enhanced pump efficiency and longevity.

- Cost Savings: Reduced energy consumption and maintenance costs lead to overall savings for industries.

- Environmental Sustainability: Energy-efficient designs help industries meet sustainability goals and reduce carbon footprints.

- Proven Reliability: With a long history of performance in critical applications, KSB pumps are trusted worldwide.

Technical Insights for Engineers and Procurement Specialists

KSB pumps are designed to solve common industry challenges such as:

- Energy Efficiency: By optimizing hydraulic performance, these pumps lower power consumption.

- Durability and Longevity: High-grade materials ensure extended service life even in harsh industrial conditions.

- Precision and Control: Advanced valve technology ensures accurate flow regulation, improving process stability.

Call-to-Action

KSB – Industrial Valves and Pumps provide unmatched performance, efficiency, and reliability for industrial cooling systems and other essential applications. By investing in KSB’s advanced fluid management solutions, industries can enhance productivity, reduce costs, and ensure long-term sustainability.

Explore more about KSB products on Nanjing XYC’s website. Contact us today for inquiries, request a quote, or browse our full range of industrial equipment to find the perfect solution for your needs.