In the competitive world of precision tool manufacturing, efficiency, reliability, and cost savings are critical. Industrial air compressors play a crucial role in ensuring smooth operations by providing consistent and high-quality compressed air for various applications. Atlas Copco – Industrial Air Compression Solutions stands out as a market leader, offering state-of-the-art technology that enhances productivity while reducing operational costs. This article explores how Atlas Copco’s industrial air compressors contribute to precision tool manufacturing, highlighting their key features, applications, and competitive advantages.

Product Features

Atlas Copco’s industrial air compressors are engineered to meet the high demands of precision manufacturing. Their key features include:

- Energy Efficiency: Advanced Variable Speed Drive (VSD) technology helps reduce energy consumption by up to 50% compared to traditional fixed-speed compressors.

- Oil-Free Technology: Ensures clean, contaminant-free air, critical for applications where even the slightest contamination can affect product quality.

- Smart Monitoring Systems: Integrated IoT-enabled sensors provide real-time performance data, allowing predictive maintenance to minimize downtime.

- High Durability: Built with premium components, Atlas Copco compressors are designed for long-term operation with minimal maintenance.

- Low Noise Levels: Ideal for factory environments where reducing noise pollution is a priority.

Industrial Applications

Precision tool manufacturing relies heavily on compressed air for various critical processes. Atlas Copco’s industrial air compressors are widely used in the following applications:

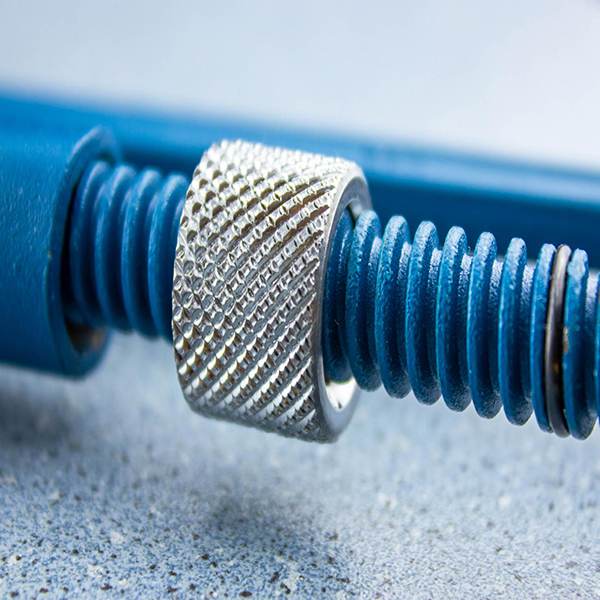

- CNC Machining: Compressed air is used for tool cooling, chip removal, and powering pneumatic tools, ensuring precision and efficiency.

- Spray Coating: Provides a steady supply of clean, dry air for consistent and high-quality paint or coating applications.

- Air Blasting: Removes debris and prepares surfaces with high-pressure air streams, improving the accuracy of machining processes.

- Injection Molding: Compressed air powers pneumatic actuators, ensuring seamless operation in plastic and metal molding applications.

- Pneumatic Tools: Powering drills, grinders, and other tools for high-precision assembly processes.

Competitive Advantages

Atlas Copco’s air compressors outperform competitors in several ways:

- Superior Energy Savings: VSD technology significantly lowers electricity costs, making operations more sustainable and cost-effective.

- Unmatched Reliability: Robust engineering ensures minimal downtime, leading to uninterrupted production cycles.

- Industry-Leading Innovation: Smart monitoring and IoT integration allow for proactive maintenance, preventing unexpected failures.

- Environmental Compliance: Oil-free compressors contribute to greener operations by eliminating oil-related contamination risks.

- Scalability: Modular systems can be customized to meet specific manufacturing requirements, whether for small workshops or large-scale industrial plants.

Technical Insights

- Pressure Range: Atlas Copco’s air compressors are available in a range of pressures from 4 to 13 bar, ensuring compatibility with diverse industrial applications.

- Flow Capacity: Depending on the model, flow rates range from 5 to 1000+ CFM, accommodating both small-scale and high-capacity operations.

- Maintenance Benefits: With features like automatic drain valves and advanced filtration systems, maintenance intervals are extended, reducing downtime.

- Oil-Free Certification: ISO 8573-1 Class 0 certification guarantees air purity, a critical factor in precision tool manufacturing.

Call-to-Action

Atlas Copco – Industrial Air Compression Solutions offers cutting-edge technology that enhances efficiency, reduces costs, and ensures precision in manufacturing. Whether you’re looking to improve energy efficiency, enhance product quality, or streamline operations, Atlas Copco has the ideal solution for your needs.

To learn more about how Atlas Copco’s air compressors can benefit your manufacturing process, visit Nanjing XYC, request a quote, or contact our team for expert guidance. Optimize your operations today with the industry’s best air compression solutions!