In modern industrial operations, air compression is more than just a utility—it’s a strategic asset. Whether powering pneumatic tools on a production line, supporting process automation in oil & gas, or running air-driven equipment in energy plants, compressed air must be delivered reliably, efficiently, and cleanly. That’s where Atlas Copco – Industrial Air Compression Solutions for industrial use make all the difference.

Renowned for their precision engineering and energy-efficient performance, Atlas Copco air compressors—when combined with the right accessories—help industries maintain peak productivity while controlling costs and minimizing downtime. At Nanjing XYC, we specialize in supplying complete Atlas Copco air compression systems and accessories that meet the evolving needs of industrial clients across sectors.

Why Accessories Matter in Air Compression Systems

When people think about air compressors, they often focus solely on the unit itself. However, the efficiency, longevity, and performance of the entire compressed air system depend heavily on its supporting accessories. From filtration and air treatment to storage and controls, each component plays a critical role in maintaining system integrity.

The Atlas Copco – Industrial Air Compression Solutions benefits extend well beyond the core compressor, offering a modular ecosystem that can be tailored to specific industrial challenges. Let’s explore these accessories in more detail.

Key Accessories for Enhanced System Performance

- Air Dryers

Moisture is the enemy of compressed air systems. Atlas Copco’s air dryers—whether refrigerated or desiccant—are essential for removing humidity from compressed air. This helps prevent corrosion, protects downstream equipment, and ensures product quality in moisture-sensitive industries like pharmaceuticals or electronics.

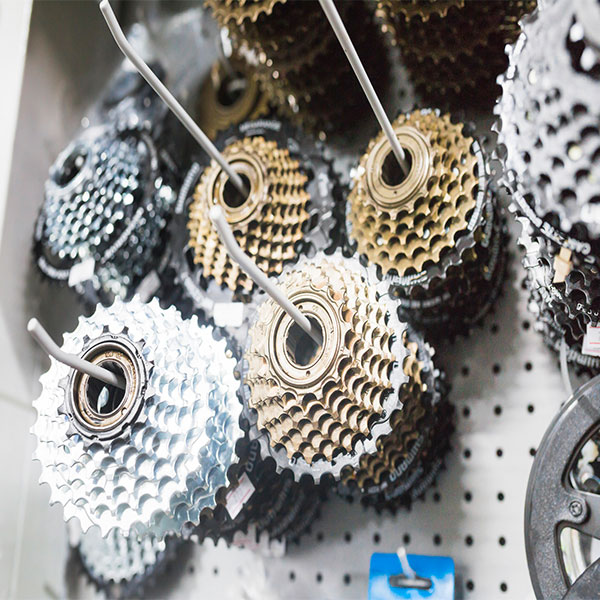

- Air Filters

Atlas Copco’s high-efficiency air filters eliminate oil aerosols, dust, and particulates from the airstream. This is critical for industries like food & beverage, automotive, and petrochemicals, where clean air is essential for safety and compliance.

- Condensate Management Systems

Proper condensate drainage and treatment are crucial in preventing system contamination and environmental violations. Atlas Copco’s condensate separators and zero-loss drains ensure safe and efficient removal of condensate without wasting valuable compressed air.

- Air Receivers (Storage Tanks)

Air receivers stabilize pressure fluctuations, reduce compressor cycling, and provide a buffer for peak demands. Atlas Copco’s tanks are built to high safety standards and are available in various capacities, suitable for all types of industrial settings.

- Intelligent Controllers

Advanced controllers like the Elektronikon® system offer real-time monitoring, remote access, and automatic load/unload cycles. These smart controllers optimize energy usage and enable predictive maintenance, helping facilities reduce operational expenses.

These accessories are not optional—they are critical components of an optimized air system. When paired with Atlas Copco’s premium compressors, they ensure reliable performance, energy efficiency, and lower total cost of ownership.

Industrial Applications: Where Atlas Copco Accessories Excel

The value of Atlas Copco – Industrial Air Compression Solutions becomes particularly evident when considering their applications across industries:

Manufacturing

Assembly lines and CNC machining rely on stable, clean air to power tools and automation systems. Dryers and filters ensure high air quality, protecting sensitive equipment and preventing product defects.

Oil & Gas

In offshore rigs and refineries, air compression systems must perform under harsh conditions. Atlas Copco’s rugged accessories support continuous operations while meeting strict safety and environmental standards.

Automotive

Paint shops and robotic assemblies require ultra-clean air. Atlas Copco’s filtration and drying systems prevent contamination that could affect paint finishes or actuator performance.

Power Generation

Whether supporting instrumentation in a thermal plant or air cooling in a wind turbine system, Atlas Copco accessories enhance uptime and energy efficiency in power operations.

Construction

Portable compressors with appropriate condensate management systems are essential in construction for powering pneumatic tools in varied environments—from tunnels to high-rise buildings.

Each of these use cases demonstrates how Atlas Copco – Industrial Air Compression Solutions solutions meet real-world operational demands.

Competitive Advantages: What Sets Atlas Copco Apart?

There are many air compression brands on the market, but few offer the breadth, depth, and innovation that Atlas Copco delivers:

- Integrated Systems Approach

While others offer piecemeal solutions, Atlas Copco provides an integrated, modular platform. Accessories are engineered to work seamlessly with compressors, ensuring optimal performance and reduced installation complexity.

- Energy Optimization

With smart controllers and energy recovery options, Atlas Copco accessories significantly reduce electricity usage—a key benefit in industries focused on sustainability and cost reduction.

- Low Maintenance, High Uptime

Accessories like zero-loss drains and long-life filters reduce maintenance needs and prevent common issues like clogging or air leaks, helping operators focus on core production instead of unplanned maintenance.

- Digital Connectivity

Remote monitoring and diagnostics tools allow engineers and plant managers to track system health, schedule maintenance, and prevent costly failures—all from a central dashboard.

These advantages solidify Atlas Copco’s reputation as a trusted partner for long-term industrial performance.

Technical Insights for Engineers and Specialists

For procurement engineers and technical decision-makers, the details matter. Consider these specifications:

- Dryers: Pressure dew points as low as -40°C for desiccant models

- Filters: Particle removal down to 0.01 microns with minimal pressure drop

- Receivers: Compliant with ASME or PED standards for safety and longevity

- Controllers: Elektronikon® Touch with multi-compressor control and IoT-ready functionality

These features not only meet global standards—they exceed them, ensuring your facility runs efficiently, cleanly, and reliably.

Power Your Processes with Atlas Copco Solutions from Nanjing XYC

Compressed air is the lifeblood of industrial operations. With Atlas Copco – Industrial Air Compression Solutions for industrial use, supported by high-performance accessories, your plant can achieve new levels of productivity, safety, and efficiency.

At Nanjing XYC, we provide full-system support—from compressor selection to accessory integration and after-sales service. Let us help you design a solution tailored to your specific needs.

- Learn more about Atlas Copco air compressor accessories

- Request a consultation or customized quote

- Explore other industrial-grade equipment to elevate your operations

Optimize your compressed air system today—experience the Atlas Copco advantage with Nanjing XYC.